Incubation system hardly affects broiler performance

Egg incubation is the first step in the broiler production chain, so full control throughout this industrial process is crucial for achieving satisfactory embryo development. During growout the incubation system hardly influences performance.

Owing to the huge importance of the hatching process, commercial hatcheries are constantly seeking ways to increase their production by raising hatchability and improving the quality and uniformity of day-old chicks. Over the last few decades, the incubation period has been about 30% of the entire broiler production cycle of about 84 days. Incubation yield is affected mainly by the overall genetic potential of broilers, egg fertility, setters, and hatchery management.

Single versus multi-stage incubators

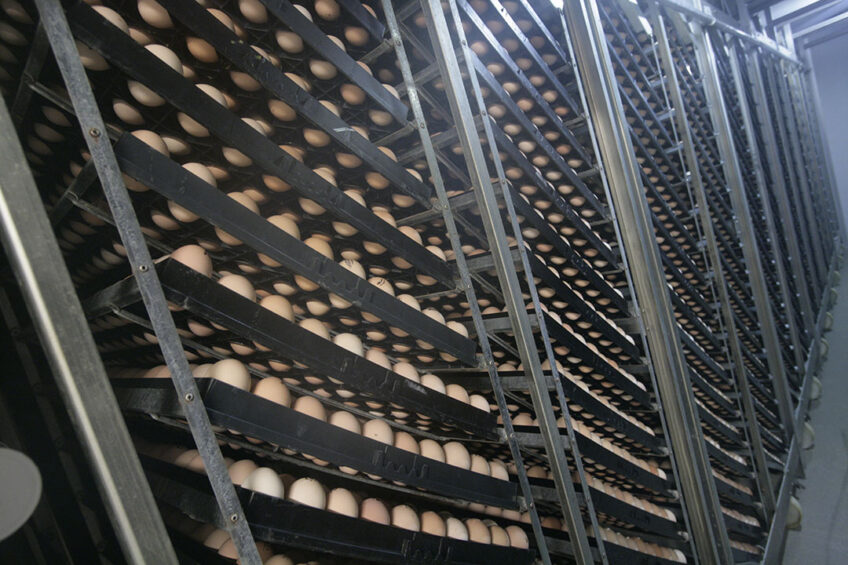

The hatchery sector has been looking for alternatives to optimise production rates, including using different systems (multi or single-stage machines) to improve incubation conditions. Multi-stage incubators set 3 or 4 batches of eggs per week such that lots of eggs from different broiler breeder farms are incubated in a single machine with embryos at different stages of development. Older embryos transfer heat to younger embryos during incubation; this heat production therefore reduces energy costs for the incubation of newly hatched eggs, making multi-stage less costly.

Single stage incubators are fully loaded with a single egg batch such that all the embryos are at the same developmental stage, which allows embryo-specific measures to be taken. These systems are recommended for incubating the eggs of modern high-yield broiler strains whose embryos generate more heat than the embryos of slow-growing strains. Additionally, a single stage incubator provides better sanitary conditions because the machine becomes completely empty at some point, thus facilitating thorough cleaning and disinfection.

Essential oils to minimise disease in broiler chicks

Researchers in Australia are investigating the benefits of native essential oils, including lemon myrtle oil and eucalyptus oil, for animal welfare, productivity and sustainability in the Australian chicken meat industry. Find out more…

Trial results

5 trials were performed to compare the use of single stage and multi-stage incubators. The experimental design looked at hatchability, hatch window, chick quality, egg weight loss and chick performance (feed intake, average weight, body weight gain, feed conversion ratio, mortality: tested in one 28-day trial). Egg weight loss between incubation and transfer was higher for eggs incubated in a multi-stage incubator. Hatchability was higher for eggs incubated in a single-stage machine, while chicks incubated in this system also had a longer hatch window. Embryo diagnosis revealed greater final mortality, with higher percentages of live and dead pipped and cracked eggs when incubated in a multi-stage incubator.

Incubator type did not affect broiler performance for any of the studied (breeder flock) ages, although male broilers showed better performance than females. Embryo requirements during embryo development, with improved hatching rates and chick quality, were better for the single-stage incubator than for the multi-stage incubator. Performance variables were not influenced by incubation type.

Authors: Mariana Mesquita, Itallo Araújo, Marcos Café, Emmanuel Arnhold, Alessandra Mascarenhas, Fabyola Carvalho, Poultry Science