Choosing the optimal feeding system for breeders

Among the many types of systems available today, what is the most effective feeding system for broiler breeders? To name a few — chain, oval pan, round pan, manual tubular, auger trough, spin feeder and manual trough.

The question really shouldn’t be which system is more effective, but which system can work more effectively in a particular operation. Most of these systems are capable of achieving desired results if managed correctly and often integrators are intent on installing the latest technology to enhance performance, when the simplest technology done correctly is just as effective.

Maximising efficiency

Of course, some systems require more labour than others and this is when it becomes a business decision to choose the feeding system that maximises efficiency, while achieving the desired results.

There is no completely automated feeding system. There are systems that can be programmed to run a certain way, but it still takes human supervision for them to run effectively. There is no such thing as ‘auto pilot’ in chickens. As managers, we tend to assume that things are as they should be without actually verifying how our programmes are being executed in the chicken house.

The purpose of a feeding system

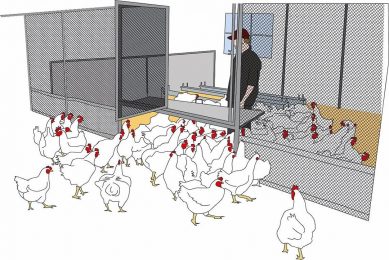

What is the purpose of a feeding system in confined animal feeding operations? A feeding system allows a large number of animals to be fed in a short time so that each gets its portion of the allotted feed for that day. The goal is for each bird to have an equal opportunity to eat an equal amount of feed simultaneously. This is the concept for any feeding system.

Flock uniformity through the life cycle of a bird is crucial in maximising the potential of any breed of chicken. The more uniform a flock, the more consistent the results will be. The more consistent are the results, the more repeatable and effective a particular program will be.

Ensuring flock uniformity

Flock uniformity starts with what and how much a bird consumes each day. Let’s assume the nutrient base and quality of the feed is where it should be. The next step is getting those nutrients to the birds equally.

Inadequate feeder space and poor feed distribution are 2 main causes of poor flock uniformity. Good uniformity in the rearing cycle is generally when +/-10% of a flock is 70-80% of the average weight for a desired weight standard. Flocks below 70% will start negatively and this will affect the production cycle; flocks above 80% are generally better performers.

Going back to the first question: What is the most effective feeding system?

Again most systems can be highly effective if managed correctly, but no system will ever be perfect. In a perfect world, we might feed each bird individually — but in reality that is not at all feasible. This is where we rely on equipment and the human touch.

As flock managers, we must decide in the field on what is best for our birds. This can only happen if we are in the chicken house watching our equipment operating and monitoring how the birds react.

Things to look out for

We can see fluctuations in uniformity on paper, but how is our feeding system operated on a daily basis? Is the feed being evenly distributed every day? Does every bird have a place to eat on the system? Is the flock attendant aware of the program? Can he or she understand the feeding system to make adjustments or call for help if something doesn’t look right?

What is the clean-up time, is the feeder too high or too low, are there breakdowns, are there feed leaks…..the list goes on and on, but none of these can be managed by monitoring a flock from weekly reports.

The human touch

It takes a hands-on approach when raising animals. We make decisions based on data, but we can never let the human touch go away. We must trust our data through verification in the chicken house.

The optimum feeding system then is the system that is properly managed.

7 key points to consider:

|

Author: Cody Polley, Director, World Technical Support Team, Cobb