Countering early losses in chick condition

Chick quality varies from chick pullout to farm placement due to procedures such as vaccination, quality control and timing of delivery.

It is vital for the farm to provide the best conditions for a fast recovery and continued chick development. Early hatching and high incubation temperatures can impair chick quality. Chicks hatching early are subject to a higher air temperature than their thermo–neutral zone of 40°C to 40.6°C, and start to dehydrate as other chicks hatch. Humidity increases as other chicks are hatching, and together the higher temperature and humidity will lead to chicks panting and losing moisture faster.

Chick dehydration

The chicks can dehydrate fast unless they are removed on time, which is why hatcheries endeavour to reduce the time the hatched chicks stay in the machine. Failure to do this will lead to many being dehydrated and overheated.

Once removed from the hatcher, the chicks should be quickly processed to remove the weak and undesirable ones so that only viable chicks go to the farms. Depending on the vaccination programme, broiler chicks may stay longer in the processing area waiting to be counted and vaccinated.

Transportation of chicks

Often, due to the lack of proper chick transport trucks, especially in countries with warmer climates, most broiler chicks are transported during the evening to provide a temperature where the chicks do not pant and dehydrate. These chicks arrive at the farm late in the evening or in the early morning and can have rectal temperatures of below 40°C. These chicks end up using their reserve energy to keep warm rather than for early chick development.

Sometimes the chicks are transported overnight and arrive at the farm at mid-morning. Here rectal temperatures can be higher than 40.6°C and chick conditions could have deteriorated. Dehydration and overheating can lead to increased mortality and culls in the first week and in the last weeks before catching. The volume of chick placement can also complicate how brooding is done. Chicks could be coming from different breeder sources and different hatcheries, and with variation in chick conditions. This can result in a high variation of chick condition which makes management much more difficult.

So what can we do?

- If the chicks are coming from various sources, it is best to plan for chicks from the same hatchery and same breeder age group, to be placed together.

- Make sure the house is properly prepared where preheating is done to ensure the temperature is similar in all areas.

- Taking a temperature reading at only one place, or relying on the sensors, can cause an uneven house temperature, leading to uneven feed and water intake and poor uniformity.

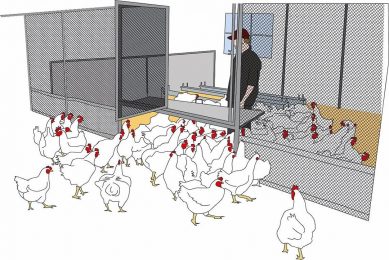

- Knowing that chicks may have lost condition, do not waste time in unloading them into the comfortable brooding area. The sooner they are placed, the sooner their condition will improve, with a goal of no further dehydration and weakness. Ensure that they are placed on top of feed with the drinkers nearby.

- Making the chicks eat as soon as they are placed will provide them with much needed nutrients, electrolytes and energy to recover. Their organs will start developing and the chicks will actively use the nutrients and antibodies from the yolk sac for their overall benefit.

- Flush water lines out just before placement to allow the chicks access to cooler water. This will make the water more attractive for the dehydrated and hot chicks to drink more, leading to recovery.

- Also ensure that the waterline nipples are not too tight as can happen with high water pressure. This results in water restriction. Especially in weaker chicks, the waterlines should have soft nipples for easy water release. Supplementary drinkers will also help weak birds get easy access to water.

Author:

Author:

Raul Elias Lopez, Broiler Specialist, Cobb-Asia