Essential ventilation management

Correct ventilation is a key aspect of bird comfort, welfare and productivity. Careful monitoring of bird behaviour will ensure that ventilation is correct for the flock as it progresses through its life.

Ventilation is a management tool which allows a grower to control bird comfort and air quality to optimise performance, bird health and welfare. The ventilation requirements of a bird changes as it grows, and with climatic conditions; ranging from providing a minimum amount of fresh air in cold weather or during brooding to creating high air speed to keep birds comfortable during hot and/or humid conditions.

Purpose of ventilation

Minimum ventilation

Minimum ventilation is used whenever the house temperature is below the set point temperature. The focus is to supply enough heat to keep the birds comfortable, and enough ventilation to maintain acceptable air quality. The house must be equipped with adequate, well distributed, heating capacity to cope with the coldest ambient temperature, while still ventilating to maintain air quality.

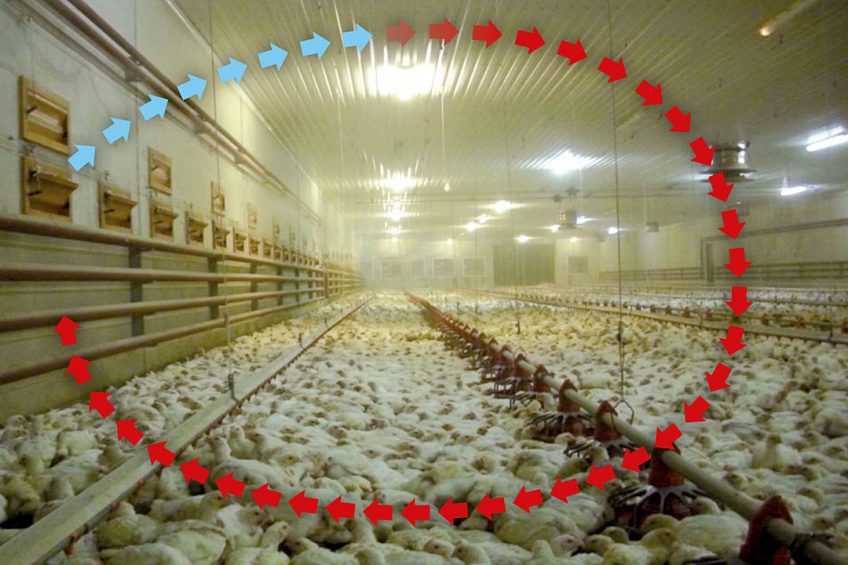

During minimum ventilation, air enters the house through sidewall inlets. The aim is to direct the cold incoming air up to the peak of the roof where warm air accumulates (Figure 1). Inlet management is a key part of minimum ventilation. Inlets operate based on negative pressure, and in order to achieve the required pressure, the house must be well-sealed and air tight.

Inlet management involves finding the best combination of;

- Minimum inlet opening (3-5 cm).

- The correct negative pressure.

- Air direction plate setting.

The inlets in use should be evenly distributed along the length of the house. Inlet air flow should be checked regularly using a smoke test or the ‘cassette tape’ method. This should be done when the house is at set point temperature, and it is cold outside.

Figure 1 – Correct air flow.

The cassette tape method involves hanging light weight strips of plastic (±10-15cm long) every 1-1.5m in front of a minimum ventilation inlet, with the last strip being in the peak of the roof. When the fans run, every strip should move, but with the movement getting less the closer the strip is to the apex of the roof. Air quality in the house is controlled by careful management of the cycle timer fans.

Transitional ventilation

Transitional ventilation begins when the house temperature goes above the set point (within 1-2˚C). The emphasis changes from maintaining temperature and air quality, to ventilating to remove heat. Fans run continuously and large volumes of fresh air are brought in from outside. The inlets still operate on the basis of negative pressure and the incoming air should be directed upward and away from the birds. As before, operating pressure should be routinely checked, and confirmed.

Due to the large volume of continuous air flow during transitional ventilation, there will be some air movement and wind chill effect on the birds. As such, pay little attention to thermometer and sensor readings and base ventilation decisions on bird behaviour.

Tunnel ventilation

The primary function of tunnel ventilation is to remove excess heat and RH, and create wind chill on the birds. Tunnel ventilation should only be used when it is clear that transitional ventilation can no longer maintain bird comfort.

During tunnel ventilation air is drawn along the length of the house creating air flow over the birds, creating a wind chill or cooling effect. The wind-chill effect alters the temperature the bird feels compared to the thermometer temperature. The number of fans running should therefore be based on bird behaviour, and not thermometer temperature. For broilers, the use of migration fences will help maintain a uniform bird and heat distribution within the house.

When all tunnel fans are operating and the birds are still showing signs of being hot, introduce evaporative cooling. The cooling system should not reduce internal house temperature but maintain it at the level as when it started.

Ideally, during maximum tunnel ventilation the temperature difference along the length of the house should not be more than 2.8°C. A well-sealed, well insulated house will improve the performance of your tunnel ventilation system. Maintenance of fans and cooling system is a key part of tunnel ventilation.

Key points to evaluating ventilation

General points

- We ventilate for bird comfort and air quality.

- So, bird behaviour and air quality are the best ways to evaluate our ventilation.

- Visit the house when nobody has been in it for 20-30 minutes.

- Upon entering the house, assess bird distribution, activity at feeders and drinker, and air quality.

- Re-asses bird comfort 20-30 minutes after making any changes.

- Keep notes of changes you make.

- Use these to update your ventilation settings.

Minimum ventilation

- Stand 2-3m away in front of a minimum ventilation inlet.

- If you can feel cold air flow any time during the cycle timer period, your inlets may be set incorrectly.

- Minimum ventilation should be increased if:

– RH is abnormally high.

– Air feels “stuffy”.

– Ammonia is high.

– Condensation can be seen on incoming water lines or house walls.

– Litter is getting wet.

- Minimum ventilation should be decreased if:

– Litter is very dry.

– Conditions are dusty.

– The set-point temperature is not maintained overnight (but air quality is acceptable).

- If bird distribution is not even around the house it could suggest:

– Cold air leakage

– Incorrectly set air inlets.

– A heater not working.

- If birds are huddling when the house is at set-point temperature, check;

– The controller sensor reading is correct.

– Set-point temperature is not too low.

- If birds are showing signs of being too hot at set-point temperature, check;

– The controller sensor reading is correct.

– Set-point temperature is not too high.

– RH is not too high.

Transitional ventilation

- If birds are showing signs of feeling cold (e.g. huddling):

– Switch off a fan.

– Check that the inlets are set correctly.

- If birds are showing signs of being hot:

– Switch on another fan.

– If at maximum transitional ventilation, switch to tunnel ventilation.

Tunnel ventilation

- If 50-60%, or less, of your tunnel fans are operating and birds are showing signs of being cold, return to transitional ventilation.

- If, prior to cooling, birds are showing signs of being cold, switch off a tunnel fan.

- If, prior to cooling, birds are showing signs of being too warm, switch on another tunnel fan.

- If all tunnel fans are operating and more than 20% of the birds are panting, then introduce cooling.

- If all tunnel fans and cooling are operating and birds appear cold, increase the cooling set-point temperature by 0.5-1.0°C.

- Vice versa if birds appear too warm.