Birds benefit from early access to feed and water

Hatching systems that enable access to feed immediately after hatching come in 2 forms. One provides feed and water in the hatcher, while the other eggs hatch in the barn on-farm and the chicks have direct access to feed and water there.

Scientific research and practical results from hatching broiler chicks in the barn often show better technical results while animal welfare is increased. However, better technical results are not always seen until the end of the production cycle. This may be caused by variables such as management factors, or the age of the parent flock. Chicks from breeders that, generally speaking, are more vulnerable, may benefit more from hatching systems that provide immediate feed and water.

In this study, which was part of the European-Chinese ‘Healthy Livestock’ project, the researchers looked at the effect of hatching systems on the technical performance, as well as early and later life welfare of broiler chickens from parent stock flocks in a semi-commercial environment setting.

3 systems examined

The research into the effect of different hatching systems on early and later life performance of broiler chickens was conducted at an experimental poultry farm in Belgium where three systems were studied in detail. In the conventional hatching system the chicks hatched in the hatchery were given no food or water and then transported to the experimental farm. This conventional system – which is the standard used all around the world – was compared with a hatcher system where feed and water were provided in the hatchery (HatchCare by HatchTech) and where the chicks remained in the same hatching tray during processing and transport to the experimental farm.

The third system studied was an in-barn hatching system where the chicks hatch in the shed. In this system, 18-day incubated eggs were transported from the hatchery to the experimental farm and placed in a Vencomatic X-Treck system. The standard procedures associated with each system were followed. For example, the eggs were disinfected during hatching in both the conventional treatment and the treatment in which the chicks were fed in the hatchery. This was not the case for the eggs hatched in the barn. Substandard chicks were also removed from both the hatchery and the on-farm hatching system.

The third system studied was an in-barn hatching system where the chicks hatch in the shed. In this system, 18-day incubated eggs were transported from the hatchery to the experimental farm and placed in a Vencomatic X-Treck system. The standard procedures associated with each system were followed. For example, the eggs were disinfected during hatching in both the conventional treatment and the treatment in which the chicks were fed in the hatchery. This was not the case for the eggs hatched in the barn. Substandard chicks were also removed from both the hatchery and the on-farm hatching system.

3 production cycles

A total of 3 consecutive production cycles were run using eggs and chicks from young breeder flocks between 28 and 31 weeks old. Per cycle, 13,860 Ross 308 broilers were placed in 12 pens. There were 4 pens per hatching system and each pen contained 1,155 animals (±20.5 chicks/m2). A standard 4-phase diet was fed with up to 40% wheat mixed in. The pens were thinned on day 32 and the remaining chicks were sent to the processing facility on day 40 for data capture.

On the day after arrival at the experimental farm various chick quality parameters were determined, such as weight and navel quality. In addition, 50 animals per pen were weighed weekly. The mortality per pen w

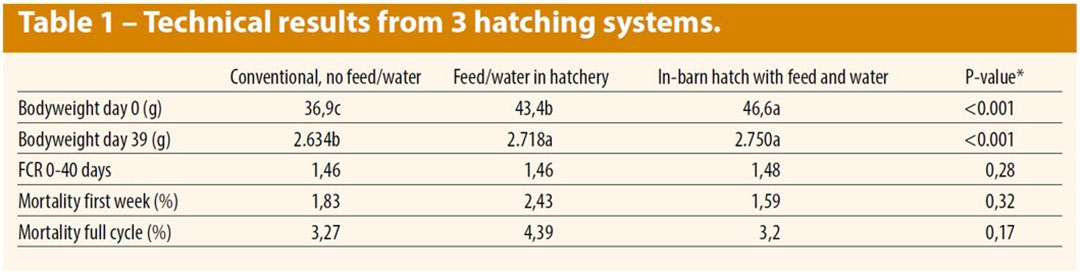

the case in the current study. There was no difference in mortality in the first week or over the total growth period between the 3 hatching systems. Compared to the conventionally-hatched chicks the bodyweight of the chicks hatched on-farm and those fed in the hatchery was higher during the whole growing period. The chicks hatched on-farm were heavier than the chicks fed in the hatchery up to day 14 but this difference disappeared after that. The feed conversion calculated over the entire cycle did not differ between the hatching systems (Table 1).

as recorded daily. Water and feed intake were recorded as well. Several welfare indicators, such as soiling, footpad lesions and locomotion, were measured at set times. The slaughter yield of 18 males and 18 females per pen was determined and breast fillet abnormalities were scored (wooden breast and white striping).

Heavier chicks

The chicks that hatched in the poultry house and those that were fed in the hatchery were heavier on the day of arrival than the conventionally-hatched chicks. However, the navel quality was worse in the on-farm hatched chicks and they also had more red hocks compared to the birds from the other two hatching systems. This was also found in a previous study and may indicate that the temperature during hatching was a bit on the high side, or that the temperature distribution in the house was was less uniform compared to the incubators in the hatchery.

Poorer navel quality can result in higher mortality in the first week but this was not

Table 1 – Technical results from 3 hatching systems

Pectoral muscle abnormalities

Pectoral muscle abnormalities were scored after slaughter. The chicks hatched on-farm and fed in the hatchery had more wooden breasts and more white striping in the fillets. The higher body weight and associated faster growth may possibly play a role in the development of chest muscle abnormalities in these test pens. No differences were found between the hatching systems in terms of animal welfare indicators, except for footpad lesions. Fewer footpad lesions were seen with the on-farm system and the chicks fed in the hatcher compared to conventional chicks.

This was also seen in previous research by Wageningen Livestock Research. The exact cause is unclear but it may be related to better bedding quality, possibly due to better digestion of the feed. In this study, the water-to-feed ratio was lower in the chicks hatched on farm and fed in the hatchery. This may have contributed to a drier litter.

Early feeding benefits

This study shows that chicks from young breeder flocks with early access to feed and water, either in the hatchery or in the barn, resulted in higher body weights and fewer footpad lesions in later life. This seems to indicate that chicks from young breeders benefit from alternative hatching systems that offer early feeding. However, more chest muscle abnormalities were found at slaughter age in chicks from both these alternative hatching systems which may be related to the increased body weight. Hatching on-farm resulted in poorer navel quality and more red hocks on hatching but with no increase in mortality in the first week.

The results were published in 2 open-source scientific articles in the journal Poultry Science. Various hatching systems have been developed that give broilers access to feed and water immediately after hatching. This reduces stress but how does it affect the technical results?