Reducing stress in heavy breeders

The poultry industry has come a long way in understanding parent stock breeds, managing equipment properly and applying the correct vaccination programme to produce the optimal number of high-quality hatching eggs and day-old chicks. One area with room for improvement is how to reduce stress in the flocks.

Reducing stress has 2 main drivers, both to respect animal welfare, which is at the cornerstone of everything we do at Cobb, and to enhance breeder productivity.

Top-9 stress points will be addressed that can be minimised or avoided.

These stressors often have a negative influence on body weight (BW), uniformity in rearing, sexual maturity, start of production, peak production and liveability of flocks.

Feedings stategies

Feedings stategies

Daily feeding is the least stressful option when caring for flocks, followed by 6/1, 5/2, 4/3 and the skip-a-day programme, respectively. Each operation should evaluate what schedule best fits the needs of the flock. To ensure correct feed distribution and avoid uniformity loss of BW, spread the feed evenly in the feeding system. Uniform feed intake can be evaluated by feeling the crops of 100 birds after the feed is cleaned up and before the female birds go for a drink. Ideally, 99% of the birds have a medium to large hard crop and only 1% with a small crop — meaning very little feed intake.

Lighting regime

Lighting regime

During the rearing period, turn lights on for the flock during the first hour of the day for birds to acclimate and drink. Provide feed 1 or 2 hours later (e.g., if you turn on the lights at 7 a.m., do not provide feed until 8 a.m. or 9 a.m.). This will train the birds that feed will not be immediately available, so they are more at ease when a person comes into the house in the early morning to check flock conditions and pick up mortality, if present. Use this period without feed to weigh the birds once each week to obtain dry weights. If you use an automatic weighing scale, operate it during this time period to get a daily dry weight sample. This concept can be continued into the production period, using this first hour instead for males to mate, as females are more available for maximum fertility. It is important to note that feed distribution should be done in the dark. Lights should be switched off during the 3- or 4-minute feed distribution, so that the birds are quiet and position themselves around the feeder track. When the feed is around and well distributed the lights can then be switched on.

Feeder space

Feeder space

Provide ample feeder space per bird in rearing based on the number of feeder loops present. The following details recommend feeder space to maintain uniformity with chain feeders. In a house that is 14 meters wide, we have 5 feeder loops via trough feeding, with 9 females per square meter (during rearing). This assumes ventilation control of the house environment. With 9.5 females per square meter in a 14-meter-wide house, that equals to 133 females/meter house length. With 2 loops working we have the following feeder space: 800 cm ÷ 133 = 6cm. This means that 2 loops can be used until 5 weeks of age (max) when a third loop will be started up. This third loop will give 1,200cm ÷ 133 = 9cm; so 3 loops can be used until 8 weeks of age. The fourth loop will give 1,600cm ÷ 133 = 12cm that can be used until 11 weeks of age. Then the last feeder loop is activated that will bring the feeder space to 15 cm (2000cm ÷ 133 = 15cm).

Vaccination

Vaccination

In countries with a high prevalence of disease and a busy vaccination programme during rearing, avoid intramuscular vaccinations in the breast whenever possible. Consider using the inguinal vaccination technique for oil-based vaccines and bacterines, which reduce stress as well as improve the overall titer level and the CV of the vaccines. It is very common to feel bumps or nodules under the skin of the breast muscle and breast keel damage caused by vaccines during fleshing evaluations around 20 weeks of age. Some vaccines, such as cholera and salmonella, are very strong and can stress the birds. Inguinal vaccinations alleviate these applications considerably.

Equipment

Equipment

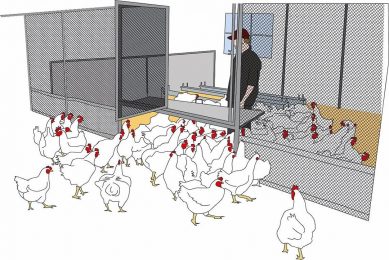

Have the same equipment between rearing and production houses to prevent the birds from suffering in unnecessary adjustment periods. If birds do not eat properly in the first few days after being moved, the whole flock can be impacted in terms of body weight and sexual uniformity. Additionally, the flock may have lower peak productions with higher culling or mortality rates to peak production. We know from experience that moving birds from pan feeders in rearing to chain feeders in production can present serious issues when using slats and community house configurations. This risk multiplies even further when working with higher female densities (e.g., 6 to 7 females per square meter).

Drinkers

Drinkers

The same is valid for the drinker system in rearing and production. Changing from bell drinkers in rearing to nipple drinkers in production — especially if they are on slats — is a major adjustment for the birds. If you are not careful, the birds can go many days without water, leading to delays in development. Note, birds can go from nipples in rearing to bell drinkers in production, but not the opposite. However, it is always better to use the same drinker system in rearing and production to keep adaptation stress to a minimum.

Maintenance

Maintenance

Be sure that the feeding equipment is working properly in the weeks after transfer and always have personnel present during feeding in the event of a chain feeder malfunction. Chain feeders can often experience alignment issues in their first week of operation; however, after this time most issues should be resolved completely.

Male management

Male management

Aggressive males between 22 and 26 weeks of age have a delaying effect on production start, liveability and peak production. If proper sexual synchronisation between females and males does not occur, house only 6% of males at 21 or 22 weeks of age and then add more males after production starts. Add the full 9% of males at 28-30 weeks of age when all the females are in production and receptive to the males. If this situation happens with frequency, re-examine the rearing period to determine what issues may be occurring.

Uniformity

Uniformity

After the birds are moved to the production house, adequate feed distribution is critical. This ensures good feather cover and helps to maintain flock uniformity. We normally feed daily from 20 weeks onward, but the amount of feed per bird is still on the low side (95-105 grams), meaning the birds consume the feed very quickly (20- to 30-minute period). Check that the birds have enough feeder space and position themselves well to eat their daily feed allotment. Consider distributing feed in complete darkness so that the complete feeder track is filled when the lights are switched on. In short, when in doubt, go back to the basics.

Author: Winfridus Bakker, Cobb