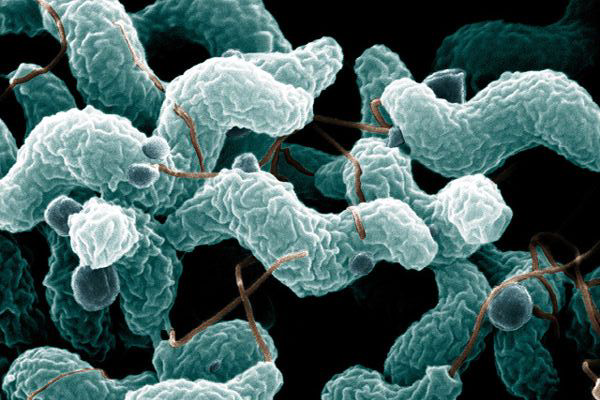

Study: Hot air reduces Campylobacter in poultry cages

A study conducted by US Department of Agriculture (USDA) scientists found that treating poultry cages with forced air that has been heated to 122o Fahrenheit (50o Celsius) can reduce bacterial cross-contamination.

While being transported in coops on trucks, poultry that have bacteria such as Campylobacter can contaminate, through their feces, other poultry that are free of pathogens. Those disease-causing bacteria can then be passed on to the next group of birds during the next trip, and so forth, unless the cycle is broken.

The researchers tested the use of hot flowing air to speed the process of drying soiled or washed cages to lower or eliminate detectable Campylobacter on cage flooring.

When the hot flowing air was applied to fecally soiled transport cage flooring samples for 15 minutes after a water-spray wash treatment, Campylobacter levels declined to an undetectable level. Static heat at similar temperatures was not nearly as effective, and unheated flowing air was moderately effective, but less so than hot flowing air.

The study, Agricultural Research Service (ARS) microbiologists Mark Berrang and Richard Meinersmann collaborated with researcher Charles Hofacre of the University of Georgia at Athens. Berrang and Meinersmann work in the ARS Bacterial Epidemiology and Antimicrobial Resistance Research Unit in Athens.

The study’s results were published in the Journal of Applied Poultry Research.