Targeting zero foreign material contamination

How can food producers minimise the financial and reputational impact inflicted by recalls? Only through taking a proactive, multifaceted approach to foreign material detection at each stage of the supply chain. Consumers expect the food on their plates to be nutritious, flavourful and contaminant-free — and rightfully so.

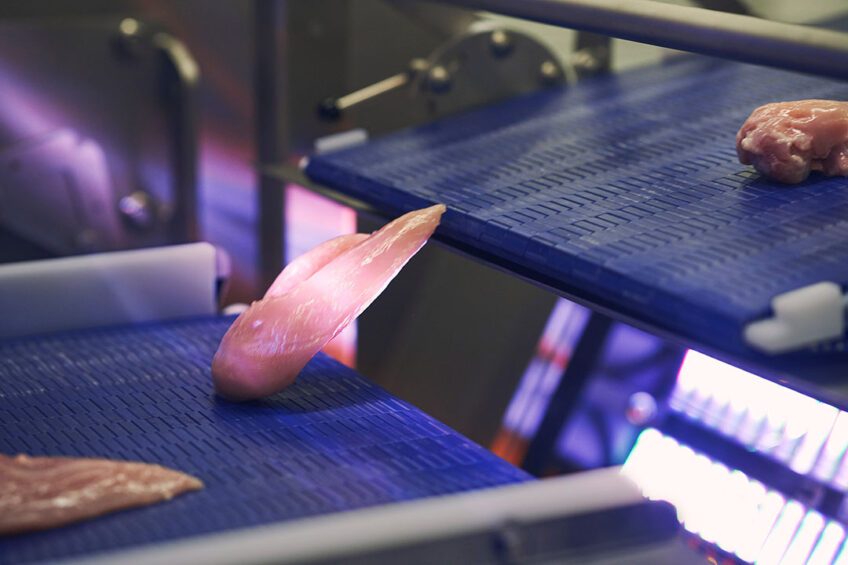

With proteins transported over long distances from the point of production to consumers’ forks, contamination opportunities abound—and each possible contamination is a potential catalyst for a costly food recall.

Can the food processing industry achieve zero foreign material contamination?

It may seem like a high goal, but zero foreign material contamination is possible. A rigorous approach to reducing foreign material contamination constitutes three factors: cultural measures, organisation-wide measures and equipment measures.

But before we work through the solutions, what is foreign material contamination and where do risks arise?

What is foreign material contamination?

Foreign material contamination occurs when a foreign object enters the food during the processing or production process. While bone, metal and glass may be the first contaminants that come to mind, they can also include plastic, jewellery, hair and fingernails, dirt, fabric, pests and parasites.

Food contamination can also be biological or chemical. However, in the context of targeting zero contamination, the containment methods focus on physical contaminants in food processing.

Cultural measures

On a cultural level, the quality of the produce ultimately begins and ends with the people involved in its processing. Companies must invest in training, implement strict dress codes, and make contamination reporting processes clear to all employees. Further, establishing a “zero-defect mindset” culture at all levels of the organisation means everyone is working toward the same goal. Every employee should take accountability and empower colleagues to take action when contamination risks arise. Encouraging this cultural shift begins with leaders modelling good behaviour.

Organisation-wide measures

Putting programmes in place to reduce the likelihood of contamination is essential. Such programmes can take the form of recognising and creating awareness of potential contaminants along the supply chain and initiating protocols to handle them. They should include raising employee awareness, documenting protocols and creating a system of assigning accountability.

Equipment measures

A key component of any contaminant detection programme is the right equipment and solutions. An effective system might include X-ray technology, metal detection, optical sorting, magnets, and separation systems. Imperatively, contaminant detection must go beyond simple end-of-line inspection with the human eye. Food processors must use detection solutions throughout the supply chain to achieve the goal of zero foreign material contamination in their consumer, retail and restaurant products.

Can you still grow your business when targeting zero contamination?

There is often a discrepancy between productivity goals and available time. This results in a constant tension between the need to operate contaminant-detection processes, and the need to keep production profitable.

However, the cost of a food recall — both in financial and reputational terms — can quickly surpass the costs of a detection process. Especially if these solutions are designed so that implementation and operation have minimal effect on the product flow.

Food recall consequences

In 2021, food recall cases have ranged from undeclared ingredients and improper packaging to bacterial contamination and parasites. No matter the cause, food recalls can have a devastating impact on a brand’s reputation, bottom line and future prospects.

A poll conducted in 2012 found that 55% of consumers would temporarily switch brands following a recall, while 15% would never purchase the recalled product again. The omnipresence of social media in the years since then has likely increased those figures further — it is easier than ever for individuals to broadcast instances of a food product falling short of the consumer’s expectations of quality, hygiene, and safety.

Food safety is in our hands

Food recalls may not be entirely avoidable, but through taking a dynamic approach to foreign material detection, they — and the damage they inflict — can be greatly reduced.

Increased awareness and advances in foreign material detection technology are helping food processors getting closer to zero foreign material contamination. As a leader in food processing solutions, Marel is dedicated to zero foreign material contamination and engaging with innovative partners to reduce contamination and increase safety and quality throughout the supply chain.