Are chicken feathers a greener alternative to polyester and nylon?

Each year, domesticated chickens in the US produce more 900,000 tonnes of feathers, which are considered a waste product. Yiqi Yang and Bingnan Mu at the University of Nebraska-Lincoln are looking to transform those chicken feathers into fibres that find a place in natural fabrics.

Yang, together with a team of colleagues, are devising and testing methods to improve the properties of feather-derived fibres. Those methods include cross-linking: chemically bonding long protein chains — including keratin, a water-resistant protein of feathers — to boost the performance of the resulting fibres and fabrics. Their work is currently funded by USDA (NIFA NEB-37-040) and by the Nebraska Environmental Trust (NET Grant 18-116).

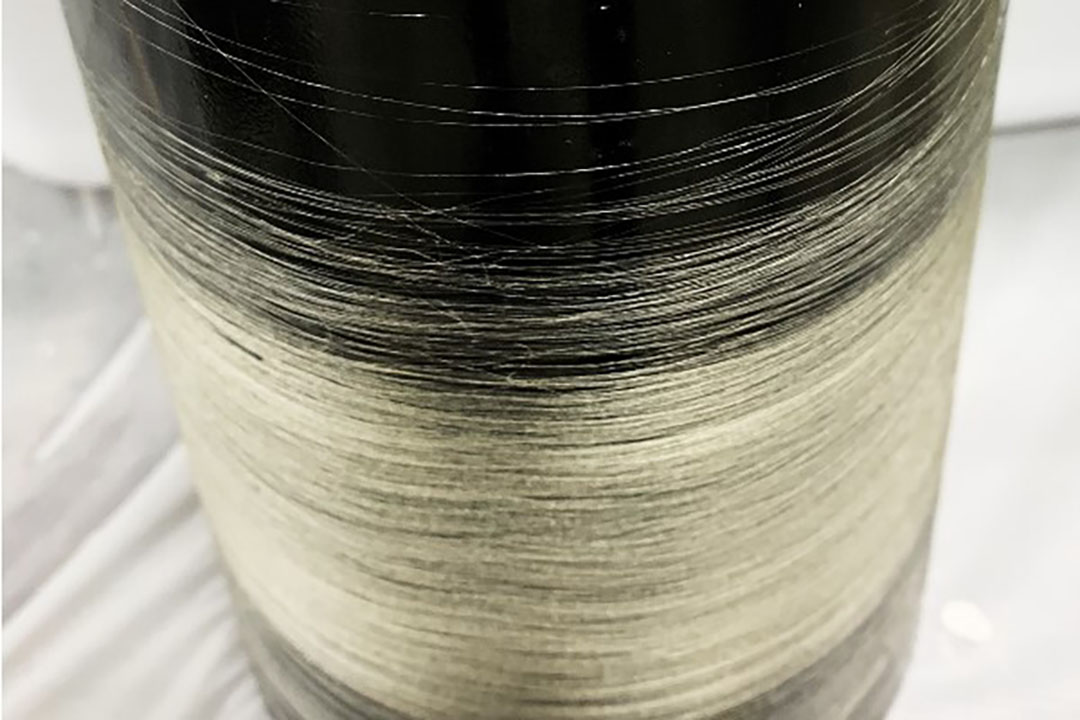

Substantially strong fibres from chicken feathers

In a recent study conducted by Yang and his team, a cross-linking class known as saccharide aldehydes was experimented with. “By modifying the molecular structure and concentration of the aldehydes, the team developed keratin fibres substantially stronger than those produced via another popular cross-linker, citric acid,” notes the university, adding that these fibres possessed 90% of wool’s strength after long-term immersion in water and 120% of wool’s strength under dry conditions.

Colour and dyes

Furthermore, these fibres retained their colour and boasted a capacity to absorb dyes that far exceeded that of other cross-linked, keratin-based fibres. The production process also yielded none of the toxic formaldehyde that has previously hounded cross-linking processes involving aldehydes.

Ongoing research

The team continues to study and develop these methods, and unwanted side effects of cross-linking need to be resolved before feathers emerge as a greener alternative to petroleum-based materials, such as polyester and nylon that currently dominate the market.

With further improvements, the team estimates that chicken feather-derived fibres could reduce the US market share of petroleum-based fibres by 10%. Meanwhile, this overlooked waste product of poultry production will be put to good use. And, according to Yang, given the low cost of feathers, keratin-based fibres would likely cost less than wool.