Automation goes hand-in-hand with variety

Making large numbers of various sausages constantly at a standard quality is a complicated business. It requires continuous checking of the raw material as well as the balance between meat, fat and the added ingredients. Traditionally, the belief is that an increase in capacity goes together with making fewer types of sausages. Today, new automation technologies increase flexibility along with making a wide range of products at a high capacity.

By Wiebe van der Sluis

All food retailers demand top quality products with a high level of uniformity in size and weight as well as consistency in colour and taste. They also force food manufacturers to compete on price and flexibility in deliveries. To meet these demands the producer needs to have full control over the entire production process.

This triggered GEA Convenience-Food Technologies (GEA-CT, formerly CFS) to look at this issue whether it could offer a solution for its clients. Although sausage makers may not immediately link the company with their industry, it has through its subsidiaries (Wolfking and Krämer+Grebe) a strong foothold in this market. For several years it successfully concentrated its work on flexibility and consistency in the preparation of the sausage content. Today it can serve the sausage industry with individual machines as well as simple lines and large scale high capacity turnkey projects.

The end of a dilemma

GEA-CT recognised that sausage making is a specialists job. It involves craftsmanship and know-how to make a constantly high quality and tasty product. Traditionally most sausage manufacturers make a large variety of sausages, and today they have to do that as cost effectively as possible. While competition is increasing these sausage makers have to choose between offering a high variety in products, which goes with low capacity, and producing fewer sausage types at high capacity.

GEA-CT recognised that sausage making is a specialists job. It involves craftsmanship and know-how to make a constantly high quality and tasty product. Traditionally most sausage manufacturers make a large variety of sausages, and today they have to do that as cost effectively as possible. While competition is increasing these sausage makers have to choose between offering a high variety in products, which goes with low capacity, and producing fewer sausage types at high capacity.

Larger operations often choose for the latter so they can highly automate their production process, while smaller scale operators tend to focus on a wider range of products at smaller quantities. Thanks to the development of new technologies both the large and smaller scale sausage makers do not have to face this dilemma any more. Now they can combine an increase in capacity without reducing the product range by introducing automated processes that create a high level of flexibility whilst consistently making a high standardised product.

Making a standardised emulsion

The first and most important issue in making sausages is the infeed of standardised raw material. Sausage makers often use a mix of locally sourced fresh and imported frozen meat of frequently changing origin. These batches can be bought at standardised fat and meat content but most of the time for cost reasons they are not. In that case the sausage maker has to measure the content and do the standardisation by himself.

The first and most important issue in making sausages is the infeed of standardised raw material. Sausage makers often use a mix of locally sourced fresh and imported frozen meat of frequently changing origin. These batches can be bought at standardised fat and meat content but most of the time for cost reasons they are not. In that case the sausage maker has to measure the content and do the standardisation by himself.

Traditionally, measuring the moisture, protein and fat content of the raw material was done by means of the conventional wet chemical analyses, a process which usually takes a full day. Besides being slow, this off-line analysis is invasive and expensive, while sampling errors of 2-4% and lab errors of 2% are common. Once the test results are available the ‘right’ mixture of meat and fat can be made. However, the question then still remains whether after grinding and mixing the fat and meat content in the emulsion is equal all over. To be sure the operator used to stop the machines and to take representative samples from the grinder or mixer before he can start the off-line analysis. This will hold up the production process for at least 15 minutes.

Continuously checking

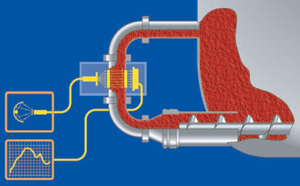

GEA-CT solved this time consuming and sensitive monitoring issue by developing an in-line fat analyser that automatically and continuously checks the exact amount of fat, protein and moisture of the fresh or frozen meat in grinders, conveyors or mixers. The real time results have an accuracy of 1-1.5% and are representative for the whole batch. In case adjustments have to be made immediate action can be taken to ensure the required product consistency. These adjustments can be made without delay or interruption, which saves time and money on every batch, and keeps the unnecessary processing and reducing the adding of low fat meat to a minimum.

GEA-CT solved this time consuming and sensitive monitoring issue by developing an in-line fat analyser that automatically and continuously checks the exact amount of fat, protein and moisture of the fresh or frozen meat in grinders, conveyors or mixers. The real time results have an accuracy of 1-1.5% and are representative for the whole batch. In case adjustments have to be made immediate action can be taken to ensure the required product consistency. These adjustments can be made without delay or interruption, which saves time and money on every batch, and keeps the unnecessary processing and reducing the adding of low fat meat to a minimum.

Field experiences have shown that the pay-back time of grinders and mixers with in-line fat analysers is very short. They not only reduce the number of hold-ups and shorten the analysis time, but also minimise through its lean point control the level of lean meat give away.

Buffer silos increase flexibility

Making a highly variable volume of different kinds of sausages often creates complex planning and production conditions. GEA-CT solved this problem by developing a unique system which allows a fully automated process with a high level of flexibility. Right after grinding and standardisation the raw material is stored in silos that are placed in a cooled chamber. The silos can buffer different kinds of raw material as well as emulsions (the mix of raw meat and ingredients ready for stuffing). These products are readily available at any time and provide opportunities for the sausage maker to take or make the exact amount of stuffing needed for that day by making use of computer controlled automatic weighing and conveying systems.

Making a highly variable volume of different kinds of sausages often creates complex planning and production conditions. GEA-CT solved this problem by developing a unique system which allows a fully automated process with a high level of flexibility. Right after grinding and standardisation the raw material is stored in silos that are placed in a cooled chamber. The silos can buffer different kinds of raw material as well as emulsions (the mix of raw meat and ingredients ready for stuffing). These products are readily available at any time and provide opportunities for the sausage maker to take or make the exact amount of stuffing needed for that day by making use of computer controlled automatic weighing and conveying systems.

Recipe data let the computer automatically calculate how much of the raw material and the ingredients are needed. Based on this calculation the various ingredients are automatically added to the raw material. A monitoring program controls the function of all systems to avoid errors and to assure a consistent product quality.

Thanks to fast and efficient transport routes, with no or little manual handling, the meat and emulsion will not be effected by oxidation or temperature changes. The raw material remains at low temperature until it is being used for mixing and stuffing. Bacteriological contamination is minimised and hygiene levels are optimised.

Better market position

The combined standardisation and silo concept allows an exact production planning thanks to the availability of raw materials with consistent characteristics and quality. This creates, for large and smaller scale producers, a huge level of flexibility and the possibility of producing the exact amount of sausages that have been ordered for that day. Besides optimising the production process the silo concept with online grinders and mixers also optimise the use of floor space. Through the optimum material flow there is a reduction in manual activity and thus less manpower is needed.

The combined standardisation and silo concept allows an exact production planning thanks to the availability of raw materials with consistent characteristics and quality. This creates, for large and smaller scale producers, a huge level of flexibility and the possibility of producing the exact amount of sausages that have been ordered for that day. Besides optimising the production process the silo concept with online grinders and mixers also optimise the use of floor space. Through the optimum material flow there is a reduction in manual activity and thus less manpower is needed.

These new developments have proven their value and allow the sausage maker to increase the competitiveness and improve the market position, not only in terms of cost but also in terms of product quality and consistency.