Achieving consistent breeder performance

The main question with regard to rearing breeders is: how can we reduce feeding errors to make rearing breeders more consistent? One solution is to stop calculating feed allocations for the week. Instead, determine the ideal feeding curve over the entire rearing period for both sexes under local conditions based on the feed specifications.

Because fewer producers are using pens to sort and correct body weights, feeding needs to follow an established curve that works best for the entire flock. An automated feeding and computing system can be used beginning on day 8. Enter a feeding curve for the entire rearing period in the computer system and allow the computer to calculate how much feed is required. Caretakers must enter mortality and culls so that the system can accurately calculate the new feed amounts for the next day or week based on the total number of birds.

The automation will work well but still requires good management and optimal conditions, including enough feeder and drinker space and good ventilation for air quality and dry litter conditions (see Cobb Breeder Management Guide for more details, available at Cobb-Vantress.com). Likewise, good uniform feed distribution resulting in uniform crop size after feeding is essential to success.

Established feeding curve

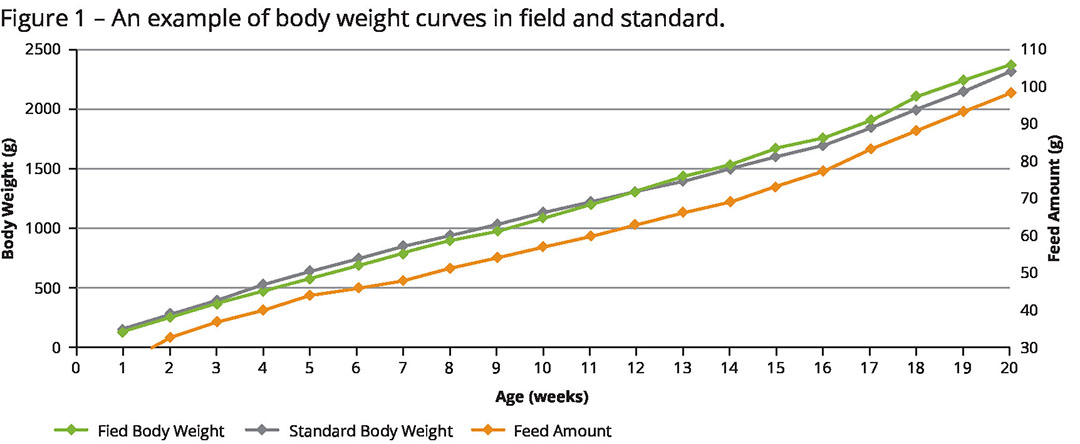

When using an established feeding curve in rearing, keep the average body weight between 98% and 102% of standard body weight and the average uniformity of the flock above 68%. Use a reliable automatic scale for the first 2 hours only and daily, when the lights are turned on and before feeding. (Like computing systems, there are precise automatic scale systems available to make weighing and data collection easy and reduce labour costs).

The scale will collect a representative daily dry bodyweight, help to track weight gain and determine whether the average body weight is on standard.

These automated methods (automated and computerized feed calculations, along with the automatic scales) should reduce human error, resulting in a more consistent programme. A reduction in feeding and weighing errors should consistently produce a prepared pullet in the right condition at transfer (20 to 22 weeks of age).

However, farm caretakers must ensure that the feed bins or hoppers are filled for the next day’s feeding cycle and that drinker and ventilation systems are working correctly. Even though a system may be largely automated, general management and checking of the equipment remains necessary.

Another point to consider is whether the feed specifications are correct. Follow Cobb’s recommendations as wrong feed specifications can cause significant issues. Even if management and all other factors are followed correctly, with the wrong feed specifications the pullets will not be conditioned properly by 20 weeks of age.

Feed increases in rearing

In rearing, the objective is to reduce stress, maintain bird growth, and achieve a minimum of 68% average uniformity. To accomplish these goals, use a minimum of 2 g/week feed increases in this period (depending on diet density). These are the general guidelines to follow.

- Ensure the 7-day bodyweight is on target and strictly control bodyweight from 2 to 4 weeks.

- From 4 to 10 weeks of age, it is better to err on the side of below the standard bodyweight rather than over the standard. This will allow 2 to 3 gramme feed increases until 12 weeks of age, at which point, the average bodyweight should be on target. Erring on the side of below the standard also prevents building a very large frame that will require more feed to maintain during production.

- From 12 to 20 weeks of age, it is better to err on the side of over the bodyweight target. This will enhance fat deposition and allow production to start earlier because the pullets have been correctly conditioned.

See Figure 1 and Table 1 for examples of field data collected using the rearing method described here.

See Figure 1 and Table 1 for examples of field data collected using the rearing method described here.

Auto scales versus hand weighing

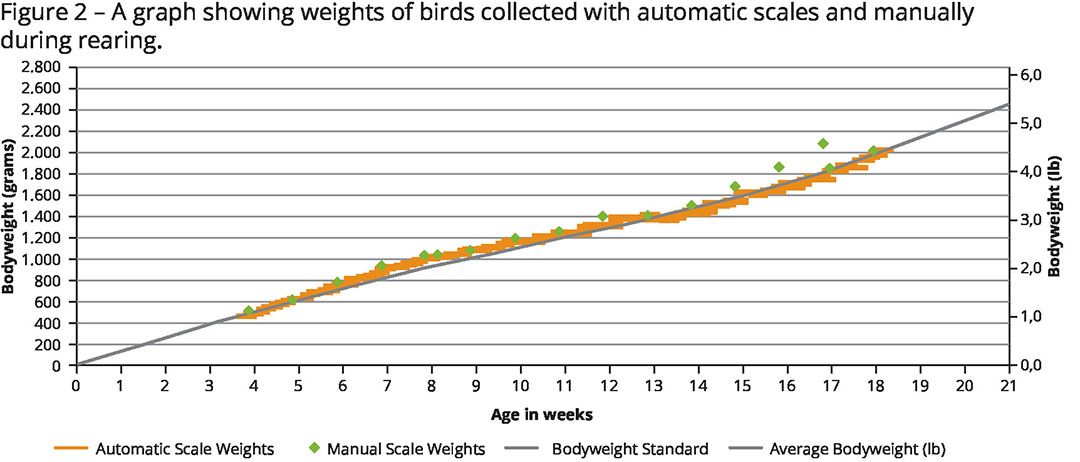

In Figure 2 the blue dots are data points collected from the automatic scale, while the green dots were collected from manual weighing. Note that after 15 weeks, the manual weights start to differ from the automatic scale weights. This occurred because the location of the manual weighing changed at 15 weeks. Manual weighing moved towards the large feed hopper where heavier birds are more prevalent. This demonstrates the importance of weighing consistently (same location, equipment, time of day, etc.) in the house.

Automatic scales can save considerable money in labour costs. Hand weighing in rearing is equal or very close to the auto scale but all depends on the sample size of the birds and the weight range used for the scale (use 30% above and below the average weight). Have the auto scale operate for 2 hours before feeding to get a relatively accurate dry bodyweight sample of around 200 birds daily.

Automatic scales can save considerable money in labour costs. Hand weighing in rearing is equal or very close to the auto scale but all depends on the sample size of the birds and the weight range used for the scale (use 30% above and below the average weight). Have the auto scale operate for 2 hours before feeding to get a relatively accurate dry bodyweight sample of around 200 birds daily.

The auto scale is very effective in rearing, and at 20 weeks of age the variation with hand weighing will be less than 2%. However, the variation increases in production. At about 25 weeks of age, the variation increases to 3% and by 60 weeks of age, the variation may be 5-6%. This variation in weighing data occurs in production because the heavier females do not go on the scales as much as lighter females.

Moreover, males may interfere with the weights. Male body weight difference compared with females at 30 weeks of age can be around 10%, which the scale would accept. For these reasons auto scales are very efficient during rearing but should not be used after 25 weeks. Building scales on the slats so that the weights of all females are measured is an option. However, it is most important to use auto scales in rearing to reduce workload and get consistent body weight and uniformity data.

Uniformity

In many countries the availability of labour limits the ability to undertake gradings. With no gradings, pens are not used in the rearing house. However, the first 8 weeks of rearing are very important to develop the frame and foster uniformity, which means the recovery of small and very small birds is important. Without the pens in rearing, small and very small birds cannot be recovered properly, and frame uniformity after 8 weeks of age will be poor.

This is especially true for breeders that come from young grandparents. A grading or sorting at 4 weeks of age of the smaller flock members (10-15%) and recovery by 6 to 7 weeks in bodyweight (frame size) is important to maintain uniformity. This same concept is valid for both males and females and means only one early grading is needed under certain conditions. Consider doing one grading at 4 weeks of age when uniformity is below 65% at 3 weeks of age.

This may occur when chicks are small at reception and when management is suboptimal in the first week. In larger chicks at 1 day of age, where uniformity is above 65% at 4 weeks of age, grading is not needed if the equipment and management conditions in the rearing house are correct and properly managed (i.e., feeding, watering, ventilation, litter conditions).

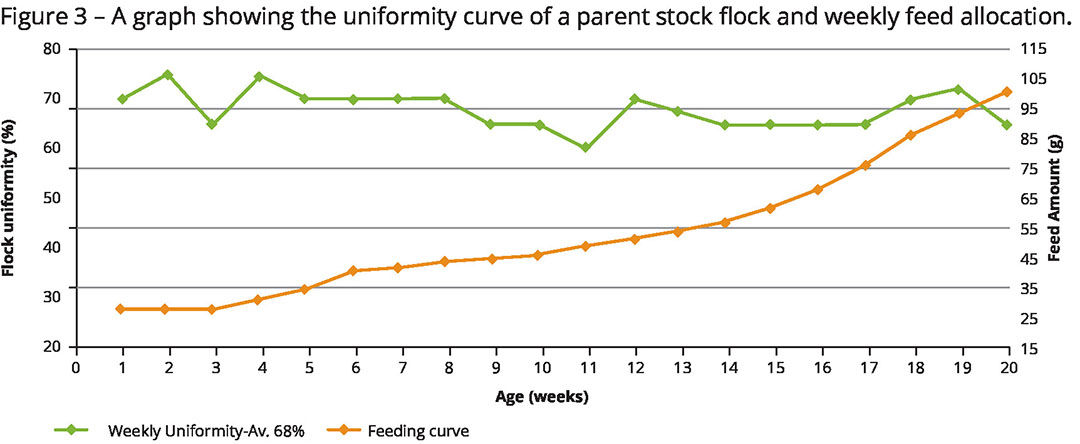

Figure 3 shows a uniformity curve that is below the target of 80%. It is important to note, however, that fluctuations in the uniformity curve are not drastic and fluctuate between 65-75%. The data indicates that – with consistent feed intake – uniformity should not fluctuate by more than 5-7% from week to week.

Figure 3 shows a uniformity curve that is below the target of 80%. It is important to note, however, that fluctuations in the uniformity curve are not drastic and fluctuate between 65-75%. The data indicates that – with consistent feed intake – uniformity should not fluctuate by more than 5-7% from week to week.

Expertise

The shortage in farm staff is compelling many companies to use more mechanical devices or automation. In the process, it appears that these devices give more consistent results for flock performance. However, controlling and maintaining the equipment is a very important aspect of flock management. For this reason, farm staff need to be more technically trained to ensure that the equipment is operating correctly and indeed delivering solid data.