DL-methionine proves more beneficial for broilers

A recent report confirmed that broiler performance has improved constantly over the past 2 decades in Germany while at the same time the feed protein content has reduced, with a resultant lowering of nitrogen excretions per bird. This development has been made possible by continuously improving amino acid nutrition, supported by improved feed analysis and increased feed grade amino acid availability.

Besides improved amino acid nutrition, the understanding of the optimal feed levels of digestible essential amino acids, including glycine and serine, for the different feeding phases has also continued to improve.

Practical recommendations can now be calculated and made (AMINOChick). The closer we get to the ideal amino acids profile, the more important amino acids in feed formulation become in terms of determining performance or limits. For example, if the concentration of one feed amino acid is below the recommended level, growth, meat deposition and feed conversion may suffer. It is therefore vital to have a detailed analysis of the individual feed components for precise compound feed production.

One key to be considered is the nutritional value of methionine (Met) sources used to balance the Met and cysteine (Cys) supply of broilers. Met and Cys are referred to as the first-limiting amino acids in common broiler feed formulations, and their undersupply is likely to result in considerable performance loss. Common macro-components for compound feeds cannot meet broilers’ Met+Cys needs.

Robust evidence

While DL-methionine (DL-Met) is predominantly used worldwide to supplement and balance Met+Cys levels in feed, the liquid Met hydroxy analog (MHA-FA) is also commercially available. MHA-FA differs from DL-Met in that in the MHA molecule the amino group typical of amino acids (NH2) is replaced by a hydroxy group (OH). From a chemical point of view, therefore, MHA-FA is, in fact, an acid which, at best, can exert an amino acid effect.

Previous studies have shown that the ileal digestibility of DL-Met is 100% and thus, in principle, the entire supplemented DL-Met should be available to the broiler for protein synthesis. An extensive study published in a scientific publication together with a meta-analysis in 2020 showed that MHA-FA is less than 100% available, with only 63% effective for growth, meat set and feed conversion as DL-Met. Evonik therefore recommends a biological efficacy of 65% for MHA-FA relative to DL-Met in monogastric livestock and aquaculture feeds. Overestimating the relative biological efficacy of MHA-FA in broiler feed runs the risk of the animals ultimately receiving less Met than assumed and thus weakening performance.

Practical trial

The University of Applied Sciences Osnabrück, Germany, investigated whether the recommended biological relative efficacy of 65% for MHA-FA holds up in practice. A total of 408,500 mixed-sex Ross 308 broilers were housed at the same time at a broiler grower in Germany. Five houses were routinely fed the standard diet containing MHA-FA; the MHA-FA was replaced with DL-Met at a weight-to-weight ratio of 100 to 65 in the remaining 5 houses. A total of 110 batches of compound feed were produced and sampled. Analyses confirmed close agreement between the amino acid contents and the expected values. The analysis of MHA-FA and free Met in the feed samples basically confirmed expectations and the experimental concept.

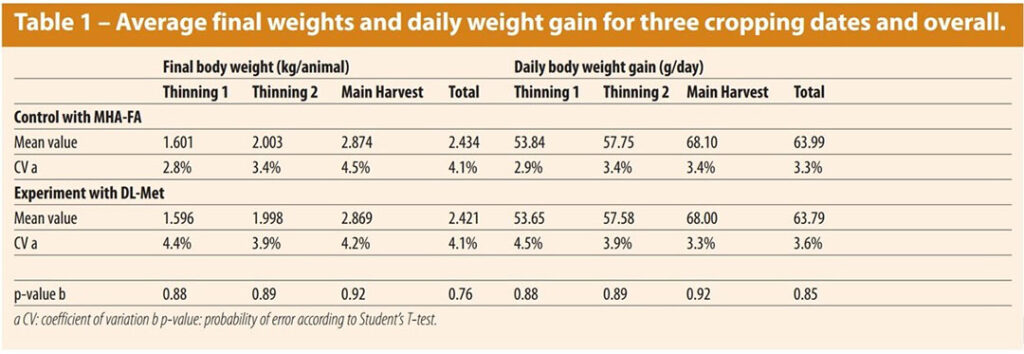

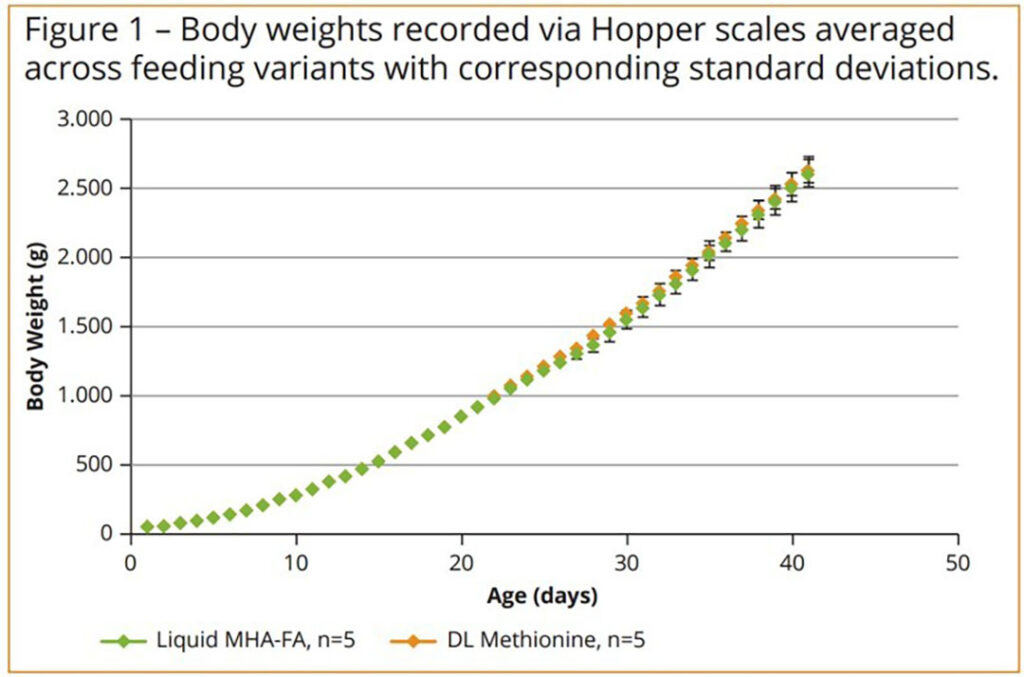

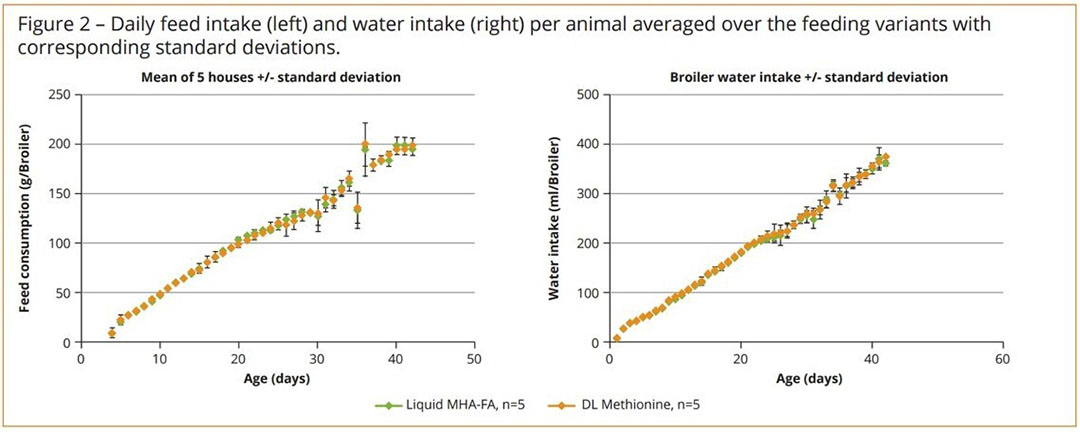

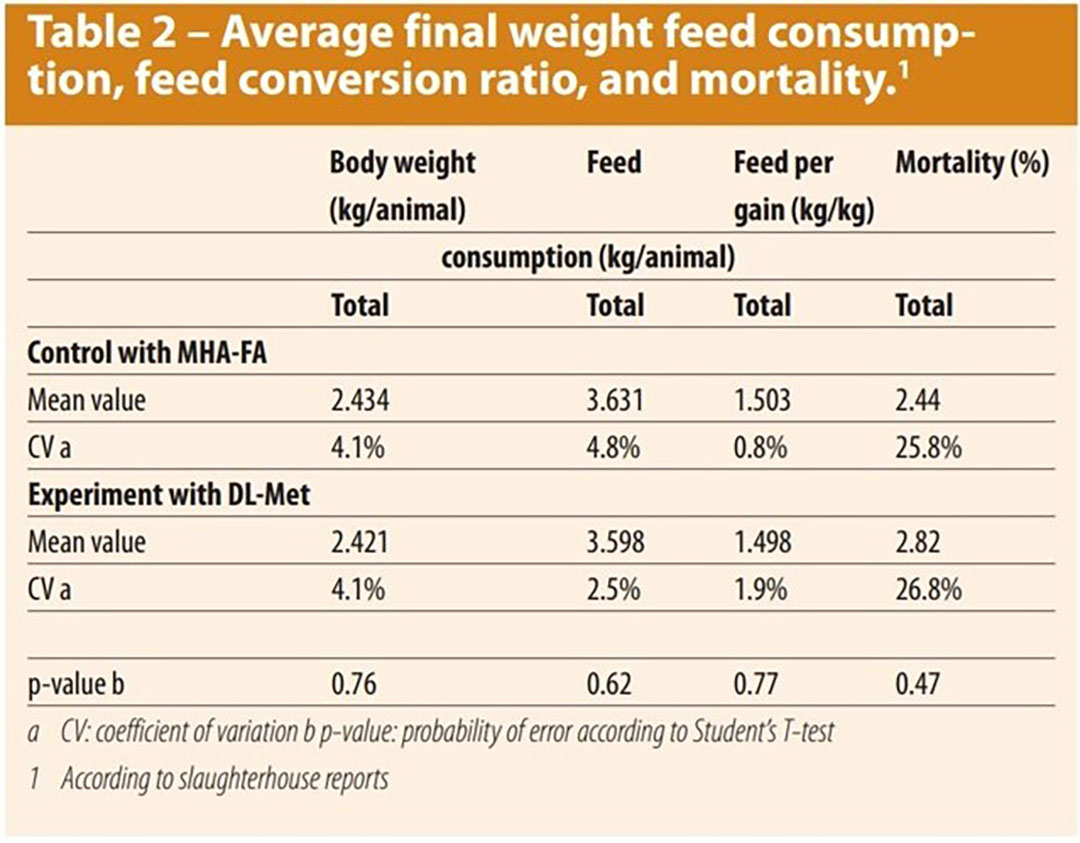

Before main harvest (day 41), 2 thinnings at days 29 and 34 cropped 24% and 15% of the birds, respectively. Overall, it may be concluded that neither at the individual harvesting dates nor in the overall mean did the 2 feed variants influence the performance (Table 1 and Figure 1). The figures shown in Table 2 do not indicate any differences for feed intake, feed conversion or mortality (p > 0.05). Mortality showed a relatively high variation coefficient for both variants but overall losses varied between 1.9-4.1% in the 10 houses. With respect to feed and water consumption, daily monitoring showed no significant differences between the feed variants, validating the application recommendation of a 65% biological efficacy of the MHA-FA over the DL-Met (Figure 2).

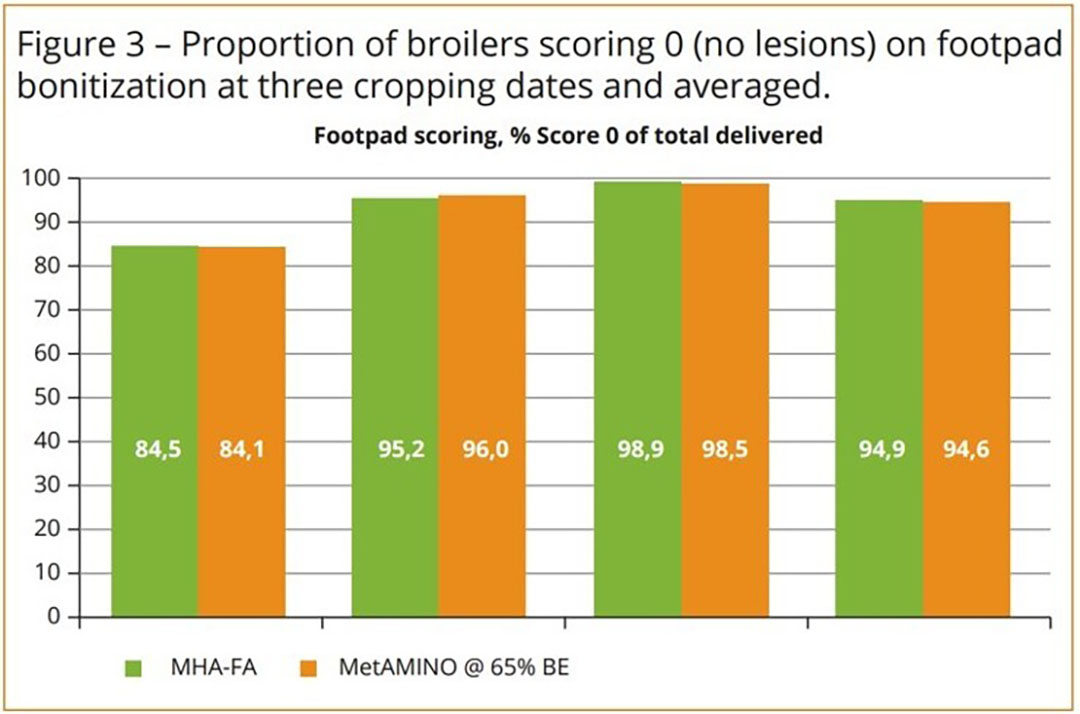

Before main harvest (day 41), 2 thinnings at days 29 and 34 cropped 24% and 15% of the birds, respectively. Overall, it may be concluded that neither at the individual harvesting dates nor in the overall mean did the 2 feed variants influence the performance (Table 1 and Figure 1). The figures shown in Table 2 do not indicate any differences for feed intake, feed conversion or mortality (p > 0.05). Mortality showed a relatively high variation coefficient for both variants but overall losses varied between 1.9-4.1% in the 10 houses. With respect to feed and water consumption, daily monitoring showed no significant differences between the feed variants, validating the application recommendation of a 65% biological efficacy of the MHA-FA over the DL-Met (Figure 2). Slaughterhouse feedback confirmed excellent footpad health (Figure 3). This data reflects good health and high animal welfare and indicates high utilisation of feed protein or relatively low nitrogen excretion. High nitrogen excretion is always coupled with increased water excretion via urine which very often manifests itself in poorer bedding quality and a related deterioration in footpad health.

Slaughterhouse feedback confirmed excellent footpad health (Figure 3). This data reflects good health and high animal welfare and indicates high utilisation of feed protein or relatively low nitrogen excretion. High nitrogen excretion is always coupled with increased water excretion via urine which very often manifests itself in poorer bedding quality and a related deterioration in footpad health.

Broilers with both treatments utilized 62% of the dietary protein (nitrogen) for deposition as body protein. In summary, the replacement of MHA-FA through DL-Met in a ratio of 100:65 did not show any performance differences in broilers under large-scale commercial conditions.

Broilers with both treatments utilized 62% of the dietary protein (nitrogen) for deposition as body protein. In summary, the replacement of MHA-FA through DL-Met in a ratio of 100:65 did not show any performance differences in broilers under large-scale commercial conditions.

According to analyses, an average MHA-FA supplementation of 2.95 kg/t was achieved. Following the tested recommendation, this can be replaced by1.92 kg/t of DL-Met without affecting broiler productivity. The commercial price ratio of Met sources is often 80% or more. Corresponding to a DL-Met price of € 2.50 per kg, the MHA-FA price should be viewed as € 2.00 per kg. Calculating the cost of the average supplementation from this, MHA-FA costs € 5.90 per tonne feed (2.95 kg/t * € 2.00 per kg) and DL-Met costs € 4.80/t (1.92 kg/t * € 2.50 per kg) and thus gives a saving of € 1.10/t feed when using DL-Met. This saving corresponds to a reduction of almost 19% in supplementation costs.

According to analyses, an average MHA-FA supplementation of 2.95 kg/t was achieved. Following the tested recommendation, this can be replaced by1.92 kg/t of DL-Met without affecting broiler productivity. The commercial price ratio of Met sources is often 80% or more. Corresponding to a DL-Met price of € 2.50 per kg, the MHA-FA price should be viewed as € 2.00 per kg. Calculating the cost of the average supplementation from this, MHA-FA costs € 5.90 per tonne feed (2.95 kg/t * € 2.00 per kg) and DL-Met costs € 4.80/t (1.92 kg/t * € 2.50 per kg) and thus gives a saving of € 1.10/t feed when using DL-Met. This saving corresponds to a reduction of almost 19% in supplementation costs.

References available on request.