Economics of slow-growing broilers

More than 200 food companies across Europe have signed up to the European Chicken Commitment (ECC) since 2018. These companies will raise their animal welfare standards to the requirements of the ECC by 2026. The Eurogroup for Animals commissioned Wageningen University & Research to undertake a project to gain insight into the costs in various EU member states associated with transitioning to broiler production systems that comply with these requirements.

Various reports have been published in recent years by Wageningen Economic Research analysing the costs associated with broiler production systems. Report 2018-116 ‘Competitiveness of the EU poultry meat sector’ calculated the production costs of conventional broilers for 9 EU countries. Report 2020-027 ‘Economics of broiler production systems in the Netherlands’ compared the production costs of conventional broilers with different concepts for slow growing broilers.

Researchers recently made a combination of these 2 reports by comparing the production costs of conventional and ECC broiler production systems for 6 EU countries, these being the Netherlands, Poland, Germany, Italy, Spain and France. The costs are expressed in euros or eurocents.

Actual data

Around 40-45% of the broilers in the Netherlands in 2021 were slow-growing broilers. Dutch farmers and partners in the production chain (hatcheries, parent stock farms, feed mills and slaughterhouses) have a lot of experience with slow-growing broilers. Therefore the production costs of conventional (fast growing) broilers and slow-growing broilers in the Netherlands were compared.

Conventional broilers (Ross308) were compared with slow-growing broilers that comply with the requirements of the European Chicken Commitment (ECC). The full standard is described in the Guidance Notes to the ECC (2022). The main criteria of the ECC are a maximum stocking density of 30 kg/m2, with thinning discouraged, the use of breeds with a higher welfare outcome, enrichment, including natural light, perches and 2 pecking substrates per 1,000 birds and the use of controlled atmospheric stunning using inert gas or a multi-phase system in the processing plant (CAS stunning).

Calculations were made for a farm with 3 poultry houses. The poultry houses have a floor surface area of 4,400 m2 in total. It was assumed that the floor surface area is fixed. By switching to the ECC standard with a lower density, this farm will keep a smaller number of broilers.

Table 1 shows the main assumptions made for the conventional broiler and ECC broiler with and without thinning. The final live weight is 2,500 grammes with a feed conversion of 1.57 for conventional broilers and 1.73 for the Hubbard Redbro. In the conventional situation the density is 20.5 birds per m2 (max 42 kg per m2 with thinning) and for ECC without thinning this is 12.3 birds per m2 and with thinning 14.5 birds per m2. One full-time worker will manage the farm with 90,000 conventional broilers (with thinning) or 54,158 ECC broilers without thinning.

Prices and other costs in the Netherlands were collected for the year 2021. This information showed that the day-old chick price of the slow-growing broiler (Hubbard Redbro) is slightly higher than the day-old chick price of a conventional broiler and the feed price in the ECC system is slightly lower than for the conventional system. As a result of the lower density under ECC, the costs of heating per broiler are higher. All these estimates are based on practical experience in the Netherlands in recent years.

To calculate the total production costs, the fixed costs, i.e., housing (including equipment), labour and general costs, were also included. The poultry house is depreciated over 25 years, and the equipment in 12.5 years. The researchers calculated the total production costs of conventional and ECC broilers with and without thinning based on the Netherlands situation and prices in 2021. The results are given in Table 2.

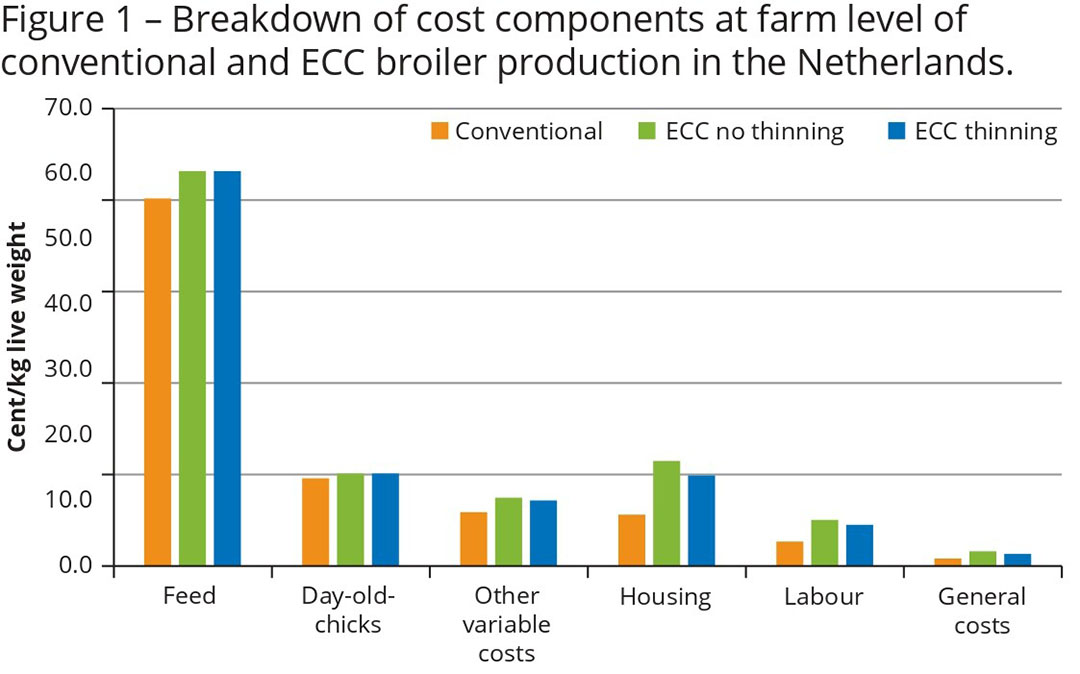

The total cost of conventional broilers (with thinning) is 92.4 cents per kg live weight. The total costs for ECC broilers with and without thinning are 108.2 and 112.3 cents per kg live weight, respectively. Figure 1 gives a breakdown of the cost components and illustrates that the ECC system has higher costs, mainly for housing, feed, labour and other variable costs (in that order). Other variable costs include electricity, heating, water, animal health, litter, catching and a few other minor cost items. ECC with thinning has a higher density on day 1, and as a result, the costs for housing and labour are lower compared to ECC without thinning.

Costs in selected EU countries

Costs in selected EU countries

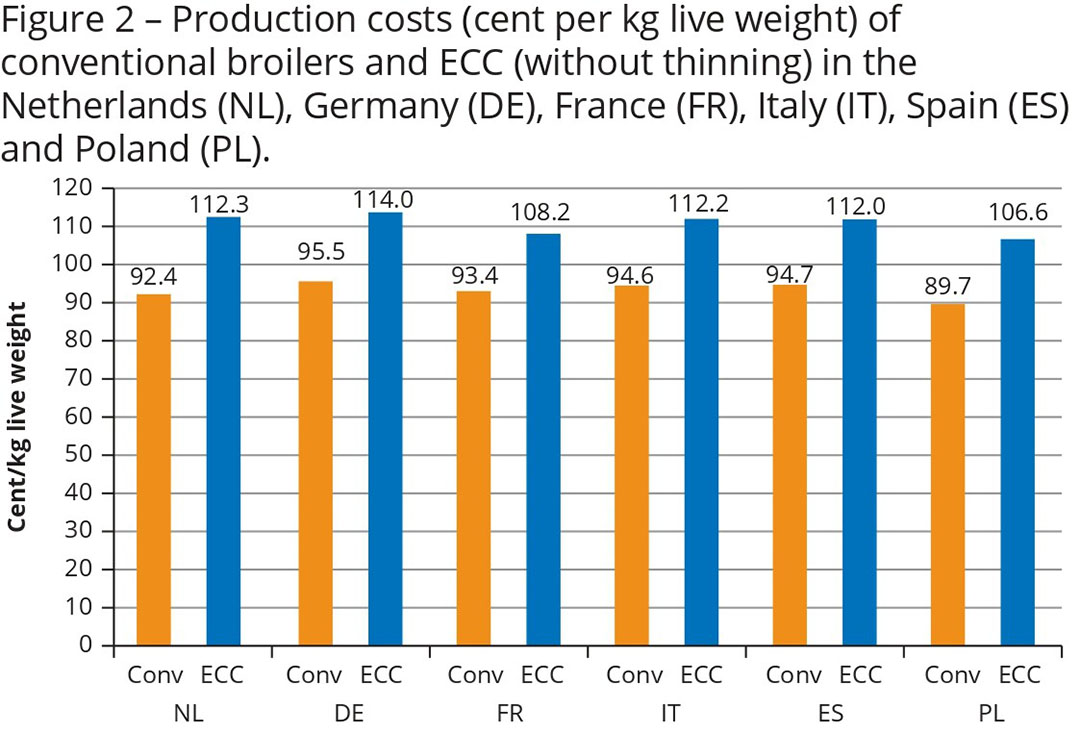

Following the same method as used for the Netherlands, the production costs for conventional broilers in 5 other countries (Germany, France, Italy, Spain and Poland) were calculated. The basic data on performance and prices in these countries were adapted from Van Horne (2018) and updated to 2021 levels. The results for ECC (without thinning) for all countries are based on the Hubbard Redbro. The production costs (in cents per kg live weight) of a conventional broiler and under ECC without thinning are given in Figure 2.

As indicated, the production costs of the ECC broiler (without thinning) in the Netherlands are 19.9 cents higher (or 22% higher) than for conventional broilers. Because of differences in production performance and prices, the results in the other countries are not exactly the same as in the Netherlands:

• Germany: the maximum density in conventional broiler farming is 39 kg/m2. This results in a smaller difference in production costs compared to the Netherlands (18.5 cents or 19%).

• Germany: the maximum density in conventional broiler farming is 39 kg/m2. This results in a smaller difference in production costs compared to the Netherlands (18.5 cents or 19%).• France: the average live weight of a broiler is 2.0 kg. Because of this lower final weight the difference in production costs between ECC and a conventional broiler is smaller (14.8 cents or 16%).

• Italy: the performance (in terms of growth rate and feed conversion) is slightly less than in the Netherlands and Germany. The difference in production costs is 17.6 cents or 19%.

• Spain: The average live weight is 2.6 kg. The difference in production costs is 17.3 cents or 18%.

• Poland: In Poland, the investment in a poultry house and labour costs are less than in the other countries. With a lower density under ECC, the difference in production costs with conventional is smaller: 16.9 cents. However, in terms of percentage, the difference is similar to the other countries +19%.

Processing costs

Van Horne (2018) gives the costs of slaughter of conventional broilers in 9 EU countries. This information was updated for the year 2021 to give an indication of slaughter costs in the Netherlands, Germany, France, Italy, Spain and Poland (van Horne, 2022). The slaughter yield for all countries is 73%. Based on this slaughter yield, the researchers converted the production costs of a live bird into costs per kg carcass weight.

The slaughter costs of a conventional broiler in the Netherlands are 40 cents per kg carcass weight. The total costs are 92.4 / 0.73 + 40 = 166.5 cents per kg carcass weight. As a result of lower labour costs, the costs of slaughter are lower in Italy, Spain and especially Poland. For the slaughter of ECC broilers, 2 adjustments were made: additional costs of CAS stunning and adjustment of the slaughter yield.

The costs of CAS stunning are difficult to calculate. The gas-stunning equipment requires more space, and modifications to the slaughter line are needed. The situation is different in every slaughterhouse. There is only 1 document giving information on the costs of CAS stunning compared to the water bath method (Sanco, 2012). It was decided to take this report as a baseline and make some adjustments for the investment and prices of input.

Because prices of water, electricity and labour are different in the 6 countries, the researchers calculated the total costs of CAS stunning and the water bath (WB) method for each country. Because there were only minor differences between the countries, it was decided to estimate the additional costs of CAS stunning to be 2 cents per bird or 1.2 cents per kg carcass weight.

Lower slaughter yield

Slow-growing birds have a lower carcass yield and a lower percentage of breast meat. This was taken into account when calculating the costs of slaughter. The carcass yield of the Hubbard Redbro is close to the yield of a conventional Ross308 broiler. The difference could be 0.7%. To include the lower breast meat yield in the calculations, the study assumed a difference in carcass yield of 1.5%. Figure 3 gives an overview of the total costs after slaughter for all 6 countries. These results provide only an indication of the costs. The situation of each slaughterhouse is different, and the market position (percentage sales to the high-end market) can vary widely.

When comparing an ECC broiler with a conventional broiler, total costs after slaughter increase on average by 28 cents per kg carcass weight. This is an increase of 18%. Between the countries, there is a range in increase from 25 cents (15%) in France to 32 cents (19%) in the Netherlands. This range can be explained by the differences in production costs at farm level.

In summary

- Shifting from the conventional system towards the ECC system (NL 2021) results in an increase in production costs of 19.9 cents per kg live weight (+22%).

- In Germany, France, Italy, Spain and Poland, the increase in costs for the ECC system compared to the conventional broiler system is slightly smaller, 16.9 to 18.5 cents per kg live weight (+18%-19%). The density in conventional systems is lower in Germany (national regulations) and in Spain (warm climate), and Poland has the advantage of lower housing and labour costs. In France, the difference in costs is smaller (14.8 cents or 16%) as a result of the shorter growing period and the lower final live weight.

- For the slaughter of ECC birds, extra costs of CAS stunning and a 1.5% lower slaughter yield result in additional costs of around 2 cents per bird, which is 1.2 cents per kg carcass weight.

- When an ECC broiler is compared with a conventional broiler, total costs after slaughter increase on average by 28 cents per kg carcass weight. This is an increase of 18% ranging from 25 cents (15%) in France to 32 cents (19%) in the Netherlands.

References are available on request.