Cantrell develops neck and shoulder skinner

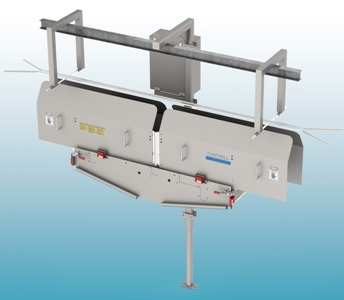

Cantrell poultry processing equipment sales and service company has developed the new NS-2004 Overhead Neck and Shoulder skinner.

The Skinner, located in-line after the cropper, uses the peeler roller system to remove skin from the neck and shoulder area of eviscerated birds. A newly designed frame for better roller support combined with a 2-hp drive creates a better skinning application.

To further the advancement of the previous “neck only” skinner in the cleaning area, Cantrell has redesigned the water rail to create a broader, more evenly spaced, water spraying application. A new design at the exit end of the NS-2004 allows for better skin removal from the support blocks of the rollers, says Cantrell.

The NS-2004 is available in both right-hand and left-hand stainless steel units for different styles of overhead conveyor systems. Cantrell has advanced the pivoted-mounting bracket for better support and easier adjustment. Capable of moving vertically, horizontally, and radially allows for a more precise adjustment to the presentation of the bird.

Cantrell states that the new skinner is designed to maximise safety and hygiene. The shields on the skinner are designed to allow access without the need for removal from the machine, eliminating the need to remove, store, and re-install shields during the clean-up process. The NS-2004 also includes a control panel to monitor a safety sensor on each access door to disable the power when the doors are out of the operating position.