Direct fed microbials take another step against salmonella

A few years ago Billy Hargis’ poultry research laboratory found how to develop probiotics – also known as direct-fed microbials (DFMs) – that would work in the drinking water of chickens and turkeys to fight Salmonella.

One of their DFM products was designated as FM-B11 and was licensed to a startup company. It then became a product called FloraMax. It was clear, however, that going to the next level was necessary.

Hargis, director of the University of Arkansas Division of Agriculture Poultry Health Research Laboratory, explained that FloraMax has been successful as a drinking water treatment to reduce the Salmonella levels in birds and ultimately on carcasses at processing.

Performance, a crucial component for the poultry industry as it determines how to allocate its dollars, is difficult to measure.

In published research, Hargis’ team has shown that meaningful improvements in production efficiency occurred with this DFM product.

Increasing stability

Problematic for some poultry producers was that FloraMax must be administered in the drinking water because it is not stable in feed.

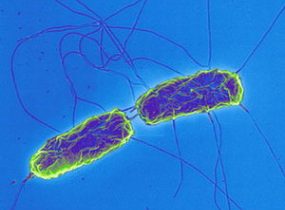

Hargis and his research team continued their project, funded by the Food Safety Consortium, and turned to development of new DFMs using bacteria from the Bacillus genus.

Some Bacillus isolates produce heat-resistant spores that could potentially be used in feed milling with easy and continuous administration in poultry feed.

Fighting foodborne pathogens is always the main focus of the research, but Hargis knows there are other factors that dictate whether the research will be applicable.

“We also realise that unless there’s an economic incentive to use this approach other than just the control of food borne pathogens, there is going to be very limited use,” he said.

Alternative to antibiotics

DFMs are beginning to be used frequently in animal feed as an alternative to antibiotics and serve as growth promoters.

For several years, interest has risen in developing new DFMs that are safe for use in animal feeds and effective for both performance enhancement and reduction of food borne disease-causing bacteria.

Such efforts led Hargis and his team to develop what ultimately was named FloraMax.

While that was a successful venture, Hargis noted, “there is still an increased need to have highly effective DFMs that are shelf-stable, cost-effective and feed stable (tolerance to the heat pelletization process) to increase compliance and widespread utilisation.”

Survive heat treatment

Bacterial spore formers from the genus Bacillus are among the DFM products being developed. Coming from specially selected spores, the resulting probiotic products can be stored indefinitely on the shelf and survive the extreme heat treatment of commercial poultry feed, Hargis said.

The research at the UA poultry health lab has identified a combination of spore isolates from Bacillus species that are as effective as FM-B11 at reducing Salmonella enteritidis in chickens and turkeys. It’s a major step.

“The ability to grow Bacillus to huge numbers of stable and cost-effective spores that can decrease pathogenic bacteria will have a tremendous impact on broiler health and productivity,” Hargis said.

The economic impact of using spore-derived DFMs can provide a financial advantage for industry along with the ability to improve food safety.

That’s why the Hargis research team discarded spore isolates if they didn’t grow to large numbers in inexpensive media.

Reducing costs

Hargis explained that the cost of reducing Salmonella creates an incentive for industry to seek ways to do so efficiently.

“If we can reduce the pathogens that cost the producer money, then it adds value to the approach of using DFMs,” he said.

“That may be part of the key to accomplishing the goal of reducing pathogens in food that comes from poultry and reducing pathogens capable of causing human food borne illness in live poultry. We’ve got to give them a return on their investment.”

It is essential, Hargis said, that the product be developed at a cost that won’t discourage its use. Finding spore isolates for feed that are capable of reducing Salmonella and other pathogens in poultry has the potential of doing the job.

“Now we may have something that we actually do in the real world that makes food safer and that companies are willing to pay for,” Hargis said.

“We’re looking to do something and trying to achieve some results. If this was easy, it would have been done before.”