Edible film kills pathogens for meat packaging

A team of food scientists in Penn State’s College of Agricultural Sciences has shown that an edible film can be used for wrapping ready-to-eat meat products to deliver a slow release of a naturally occurring antimicrobial agent capable of killing a foodborne pathogen.

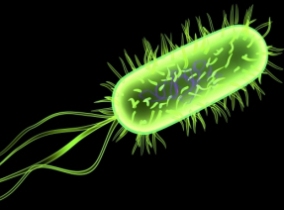

In the study, which was published in the March issue of the Journal of Food Safety, the researchers demonstrated the effectiveness of pullulan films containing antimicrobial sakacin A to control Listeria monocytogenes growth.

The research team – which included Catherine Cutter, associate professor of food science, John Floros, professor and head of food science, and Valentina Trinetta, a visiting scholar from the University of Milan, Italy – also confirmed the feasibility of using active pullulan films to deliver a bacteriocin directly to a food surface.

Sakacin A is a bacteriocin produced by a strain of Lactobacillus. “It’s a naturally occurring antimicrobial produced by organisms associated with fresh meats,” said Cutter, the lead investigator. The compounds are created during fermentation processes, and when applied to meat, they restrain the growth of Listeria monocytogenes.

“Controlled release of such agents from packaging films could inhibit the growth of target microorganisms over time. We think edible films enhanced with these bacteriocins could be placed between slices of pre-sliced deli meats to give the product extended protection against pathogens.”

Pullulan film is a biopolymer, polysaccharide film produced by the fungal organism Aureobasidium pullulans. It is a colorless, tasteless film that is resistant to oil and is largely impermeable to oxygen.

“Pullulan films require less antimicrobial, demonstrate longer antimicrobial activity and allow for controlled migration of the microbial molecule from film to the food matrix, as compared with the direct addition of sakacin A to ready-to-eat meat products,” said Cutter.

This microbial polysaccharide has not previously been exploited as a delivery system for bacteriocins, according to Cutter. The aim of the Penn State study was to evaluate the effectiveness of sakacin A against strains of Listeria monocytogenes that have caused foodborne outbreaks and to study the efficacy of a pullulan film containing sakacin A to control the growth of the pathogen in turkey deli meat.

Increased use of synthetic packaging films has led to ecological problems due to their failure to break down in the environment, and Cutter noted that consumers are demanding that food-packaging materials be made of bio-based materials that are biodegradable and recyclable.

“Because consumers want packaging materials to be ecologically friendly and biodegradable, novel food-grade packaging materials and/or technologies are being developed to meet these new trends, such as the use of biopolymers from agricultural and marine raw-material sources,” she said.

“The incorporation and slow release of antimicrobial agents in packaging materials may provide a means of extending the bacterial lag phase, reducing microorganism growth rate and extending the shelf life of foods. Bacteriocins are compounds that can be used as a means of biopreservation.”

The researchers found that when experimentally inoculated surfaces of turkey breast were treated with pullulan films, Listeria monocytogenes populations were reduced dramatically after 3 weeks under refrigerated storage. These results demonstrate the possibility of using sakacin A-containing pullulan film to inhibit or reduce the pathogen on the surfaces of ready-to-eat foods.

“This packaging material has some really neat properties,” Cutter said. “It is nearly as strong as plastic now used for meat packaging, and it is completely edible. It won’t necessarily replace the material used in vacuum packaging meat now, but it maintains the integrity of product and has the potential to improve shelf life… As soon as the pullulan film contacts a moist surface such as meat, it meshes right into the surface, and as it dissolves, it releases the antimicrobial.”

Source: Penn State