Glycerol: A possible ally

The recent crisis of grain prices and supply is putting constant pressure onto poultry producers. What’s worse is that it does not appear that the current situation will get much easier very soon. In fact, it may worsen. New possible ways to deal with this problem need to be explored. Glycerol is an option here.

By Dr Rogério G. T. da Cunha, Sao Paulo, Brazil

The current crisis of grain prices and supply has been experienced by poultry producers for some time now. The reasons behind this situation are complex and multifold, and basically have three roots. The starting point was the political decision of the US to foster ethanol production from the rather ineffective corn source. The second is biodiesel production (in some places) from soy oil, also ineffective when compared to other oil sources, along with the loss of soy land to maize. Thirdly, the increase in world demand for grains for both human and animal consumption. Animal producers have to adapt to this new situation and find innovative ways to deal with it. At present, the situation seems to be most critical in relation to corn, the prices of which were soaring in 2008.

At the IX SBSA (Symposium South Brazil of Poultry farming), Dr Antônio Mario Penz Junior, researcher at UFRGS (Federal University at Rio Grande do Sul) and technical director of Nutron Alimentos Ltda, and Mario Gianfelice (Master’s student at UFRGS). Dr Penz presented a paper on this issue focusing on some possible ways out. Dr Penz talked specifically about DDGS and glycerol, by-products of the production of biofuels, which can be used in animal feeds.

The Brazilian perspective

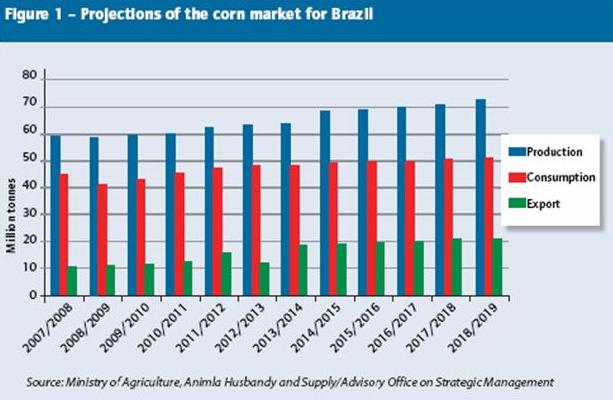

From the strict viewpoint of supply, Brazilian animal production should not be affected much. After all, the country is a net exporter of both corn and soy. In addition, projections show that it will remain so for the coming years (See Figure 1 and Figure 2 – note that prices are in local currency, but the trend is evident). Production of both basic feed ingredients is expected to increase in the years to come. Most relevant here is that corn is not used in Brazil for ethanol production – the country employs only sugar cane for that aim.

However, it was not stated if the projections for corn took into account that international price increases may favour exports at the expense of domestic consumption. As for soy, they explicitly did not consider its use for biodiesel production. In any case, there are indications that the government may resort to strategies of export restrictions in case internal supply is threatened more seriously. However, when it comes to prices, the situation might not be exactly the same as for the supply. Here, the external prices will probably push internal ones as well (Figure 3). “I believe that grain prices will stabilise at a high level, but the meat prices will remain stable and relatively low,” said Dr Penz. Then again, the search for alternatives is also on the agenda of Brazilian producers, researchers and companies, as elsewhere in the world. This is where glycerol comes in.

Glycerol is a possibility

Glycerol is a small molecule generated as a by-product of biodiesel production. “Studies have demonstrated that for every litre of biodiesel produced, 80 g of glycerol are generated as by-product,” said Dr Penz. However, he recalls that glycerol is also produced in the course of complete digestion of some kinds of fat, the triglycerides (which are nothing more than three fatty acid chains bound to a glycerol molecule). It is thus a well-known substance by the physiological systems of animals. Dr Penz goes on to say that glycerol is easily absorbed by the gut through simple diffusion, given its small molecular weight and size. In addition, it is used in metabolic pathways for energy production. Recent research experiments have shown that glycerol metabolisable energy values approach its gross energy ones, which shows it has high digestibility. He also lists some practical consequences in the making of the feed: when used in appropriate concentrations it improves pellet quality; it decreases pelletising energetic costs, and; it can reduce the powder in the feeds and supplements. Furthermore, some authors suggest it can improve palatability because of its sweet taste. The logical conclusion from the above is that it can (or should), in principle, be used in feed formulations as an energy source.

The right amount

Combining evidence from several works, Dr Penz recommends that the amount of glycerol in the diet should not exceed 5%. “Greater amounts have resulted in some problems for broilers, such as decrease in carcass quality, and productivity losses. The same could not be said of layers though. In any case, however, metabolisable energy (ME) decreased with the increase in concentration for both broilers and layers,” he detailed.

The explanations for the above problems seem to be varied. According to him, some authors suggested that decrease of pellet quality could explain yield and quality losses. This would reduce the pellets’ ability to flow adequately in the feeders. “However, the decrease in ME is probably connected to the problems in a direct way, since it decreases feed conversion rates. The authors who recorded the overall reduction in ME suggested that the explanation for it lies in the lack of renal reabsorption of glycerol. The consequence is its elimination in urine.

The excess of the substance in the blood, on its turn, derives from the low speed of action of the enzymes that deal with glycerol. On a cascade of consequences, this also leads to an increase in water consumption and excretion, so as to get rid of the excess glycerol,” continued Dr Penz. The results of increased water excretion are predictable – more fluid faeces and damp beds or cage floors.

The bottom line, therefore, is that glycerol is a viable and interesting alternative, provided it is used in the right concentration, so as the lemonade does not go back into a lemon.

Necessary care

The substance still hides other secrets. A series of further care are to be taken when using glycerol in feed formulationsif one wants to avoid trouble. The good news is that all the problems can be summed up into one issue: product quality. According to Dr Penz, the first point of concern here is the presence of residues of methanol. This is a highly toxic substance that may be used in the biodiesel production process. “Some researchers found variation in residual amounts of the substance among different glycerol samples. If present in quantities above tolerance levels, it can cause severe health problems to the animals,” he said. They also conducted a research project at the labs of Nutron Alimentos Ltda. on another relevant issue – variation in product composition. At first sight, one could rightly consider that a pure substance should not have such variation. However, Dr Penz explains that this happens exactly because of differences in purity. The efficiency of the biodiesel production process is another component of the differences. These are found in relation to many aspects: energy levels, presence/amount of minerals (or even of heavy metals such as lead), pH, and moisture.

“Most importantly, we need to pay attention to the gross energy levels and the amount of sodium. For one to have an idea, we found variation from 3,830 up to 6,367 Kcal/kg of gross energy. Regarding sodium, the interval we found was between 0.6 and 2.6%, a far from negligible variation,” detailed Dr Penz. He argues that such disparity, along with the one on methanol figures, may restrict our free use of the substance. Thus, we may conclude from these findings that extra care should be taken with the quality of the product and the reliability or the supplier. Alternatively, one may resort to having the quality constantly checked, either on the farm or through an accredited lab. Having done that, and following the formulation rules above, we have another option at hand to help go through the difficult times ahead regarding feed prices.