Intelligent cutting 2.0 maximises efficiency

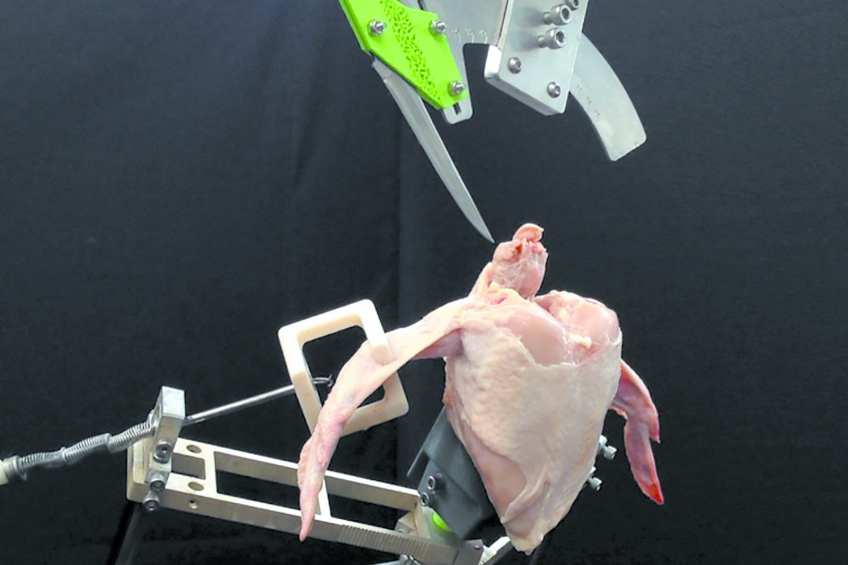

The new experimental robotic, intelligent ?cutting and deboning system of GTRI, uses machine vision and robotics to sever the ?tendons and joints on bird front-halves in ?preparation for the removal of the wings and breast meat, also known as a butterfly cut. It maximises preciseness, yield and quality.

By GTRI, Atlanta, GA, USA

Researchers at the Georgia Tech Research Institute (GTRI) recently completed the first year of a three-year project to rebuild their Intelligent Cutting and Deboning System, with the goal of making it into a bionic poultry deboner that can rival the cutting skills of the most experienced human.

The system uses machine vision and robotics to sever the tendons and joints on bird front-halves in preparation for the removal of the wings and breast meat, also known as a butterfly cut. The objective is to make cuts that maximise yield while eliminating bone chips in the cut meat. Because it combines advanced robotics, image processing, and statistical modelling in one device, the system can think and react to its environment just like a human. Only it can do it better and faster. This makes it particularly unique compared to other fixed automation systems.

“The ongoing challenge with automating the deboning task has been creating a system that can handle the natural variability of poultry products. What makes our system ground-breaking is its flexibility and ability to customise cutting motions regardless of the bird’s size,” explains Dr Ai-Ping Hu, GTRI senior research engineer and project director.

Increased dexterity

The so-called Intelligent Cutting 2.0 System has substantial hardware and software enhancements compared to its predecessor. The most significant advancement is its move to a 6-degree-of-freedom knife robot. Unlike the previous 2-degree-of-freedom system, six degrees better approximates a human’s wrist and hand. This increased dexterity allows researchers to experiment with a wider range of cutting motions and geometries to arrive at optimal cuts.

Next, advanced image processing algorithms are an order of magnitude better than previous methods. According to Hu, the system is now achieving milli-meter-level accuracy in predicting the bird’s internal structure. This increased robustness allows the robot to define correlations between the bird’s external features and its internal joint structure — essential to making a clean cut, i.e., not cutting into bone. Lastly, a new graphical user interface, or software wizard, streamlines the various processes of a bird cut, while data analysis of cutting motions made by human deboners helps to determine the optimum knife paths needed to make precision cuts.

Interestingly, analysis of motion capture data has shown areas of the bird that the human is not as efficient at cutting as a robot. Hu says this last finding is particularly exciting to researchers as it is an indication that the robot will indeed maximise the amount of meat removed from the carcass, thus increasing yield.

Maximising yield

Yield amounts mean a lot to the poultry industry — quite simply, higher yield equals higher profits. “Because a robot’s motion is agile, faster, and more precise, there are certain portions of the front-half cut that a robot can perform that can possibly result in a half to one percentage point more yield per bird,” says Hu. Additional tests and refinements to the system are underway, and the team is pursuing industry partnerships that can help push near-term commercialisation.

“Our hope in the remaining two years of the project is to build a prototype machine that more resembles plant-ready equipment. We are also considering how existing commercial deboning equipment can be retrofitted with our technology,” Hu concludes.

Reprinted from PoultryTech, a publication of the Agricultural Technology Research Programme of the Georgia Tech Research Institute, a programme conducted in cooperation with the Georgia Poultry Federation with funding from the Georgia Legislature.

[Source: World Poultry Vol 30 nr 2, 2014]