Moba ready to face the future

Since 1947, Moba has progressed from a producer of egg grading machines to a technology company that develops high-quality systems for the egg industry. And now with the new modern headquarters in the Netherlands, Moba is ready to face the future and take the egg industry to the next level.

In recent years Moba has experienced enormous growth, due to the higher demand of eggs and global urbanisation. Moba’s answer to these recent societal developments is to design innovative total solutions that allow egg producers to increase their capacity whilst ensuring product quality and also keeping food safety requirements in mind.

The quest for the perfect egg

Food production margins are thin, which is why egg producers measure success based on the optimal use of eggs and the minimisation of losses. Before eggs are packed into trays, they are weighed, graded and checked to ensure only the best eggs make their way to the consumer. Important features in this process are the detection systems that guarantee the quality of the eggs. These systems use the latest technological developments, such as using acoustic analysis to detect cracks or using LED lights and spectrum analysis to detect blood, to separate top-quality eggs from eggs of a lower quality. These lower-quality eggs can be used, for example, in cosmetic products. It is important that the detection systems are as accurate as possible. Ensuring the eggs are used in the best possible way has not only financial benefits but it’s good for the environment too: Valuable food is not unnecessarily thrown away and waste is reduced.

The industry is constantly changing, technologies that are available today were unimaginable a few years ago. This means that more tools are available to aid in the quest for the perfect egg. As a pioneer in the industry, Moba is determined to implement these techniques into its egg grading equipment to guarantee the highest possible quality. For example, the company is currently working on a futuristic development programme that aims to incorporate artificial intelligence into a vision system to aid in the detection of hairline cracks in eggshells.

Importance of food safety

A recent salmonella outbreak in North America once again underlined the importance of upholding the highest hygiene standards. That’s why Moba designs grading machines with the highest standards of hygiene in mind, so that the eggs are both of top quality and safe to eat. Detection systems are of great help in this process. How? Detection systems remove bad eggs at the earliest possible stage. In spite of this, certain machine parts still come in contact with these eggs. These machine parts would pose a contamination risk for good eggs, were it not for the state-of-the-art technology in use. UV-C light ensure that! Even during the production process, bacteria and other micro-organisms just don’t stand a chance.

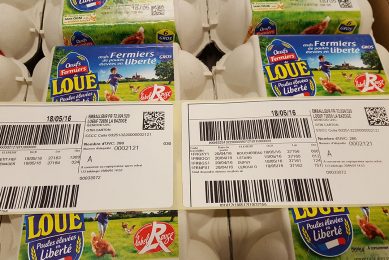

In addition to these techniques for ensuring the highest possible level of food safety, a robust control system also helps to establish a food supply chain that is both transparent and responsible. When safety issues occur, the source of these outbreaks needs to be identified as quickly as possible. Moba grading machines keep track of the origin and destination of each egg throughout the entire process, making it possible to follow the journey of each egg right up until it reaches the supermarket shelf.

Total solution

Efficiency and food safety are paramount at every step of the egg grading process, from the moment the eggs arrive at the grading machines until the moment they are finally stacked on the pallets. Moba designs innovations that provide total solutions; a task that Moba took upon itself many years ago and one that the company is improving every single day. And with the new building in Barneveld the Netherlands, Moba can take the next step towards developing the company and ensuring its continued growth in the future, all so that it can continue to provide the customers with revolutionary solutions.