The world’s first commercial automatic chicken sexing machine

Currently, it still remains extremely challenging and laboriously to identify the sex of day-old chickens. According to statistics, human operators require training for at least 3 months to grasp the skills of checking the sex of a chick with the naked eye. But, what if a chicken’s gender can be identified by an automatic sexing machine?

Precision is largely subject to human learning ability, age and mental state. Younger sexers performed much better than elders due to good eyesight and learning ability. Usually, a person needs to work 8-10 hours per day. Fatigue, distraction, and bad mood are all factors that could influence their identification accuracy. Typically, at peak hours, versed sexers can reach 97% accuracy rate, but when they get tired, at least 3% will be deducted. Due to high training costs, age, skill and sight requirements, payoff of chick sexing industry is extremely high, normally more than US$60,000 annually in western countries.

A solution to identify chicks

How to identify the gender of chicks automatically has puzzled poultry companies for a long time. Luckily, there is a solution. The world’s first commercial use chicken vent sexing machine was invented by Shanghai Xiashu Intelligent Technology. Powered by artificial intelligence, the machine can identify white and colored broilers, layers, and turkeys with 98.5% accuracy and 1,000 chicks per hour and has been adopted in many grandparent plants worldwide.

“Artificial intelligence and computer vision technology in deep learning can accurately identify the sex of broiler and layer chicks, reducing high labour costs and improving efficiency in the hatchery,” according to Bowen Cai, research scientist and managing director of Xiashu Tech.

Cai and his colleagues at Xiashu Tech graduated from the University of Pennsylvania, University of Michigan, and Harvard University in the US and founded Xiashu in 2017 when they were PhD students. This company ranked No.7 in the world artificial intelligence competition of Big Data Expo in China and is now the fastest-booming company at Shanghai Tongji University Science Park.

Broilers, layers and turkeys

Xiashu’s research team spent 4 years collecting a huge amount of data for different kinds of broilers, layers, and turkeys to build the model. The first machine was sold in 2021 in China for yellow broilers and now both the accuracy and efficiency have been validated by tens millions of chickens over the past 2 years.

The Xiashu chicken vent sexing machines have been sold to many customers in China, the US, Australia, Indonesia, Malaysia, Thailand, Myanmar, Philippines, etc. Companies such as EW group, Aviagen, Cobb, Lohmann, CP group, Japha, Wilmar, Wens, Lihua, Leung Hup are all users of the vent sexing machine.

“This machine is very easy to operate. We will send technicians to customer hatchery plant to teach them how to operate the machine and conduct routine maintenance. Anyone can be versed sexers within a 5-day training session. This machine is now quite popular among big hatchery plants,” said Cai.

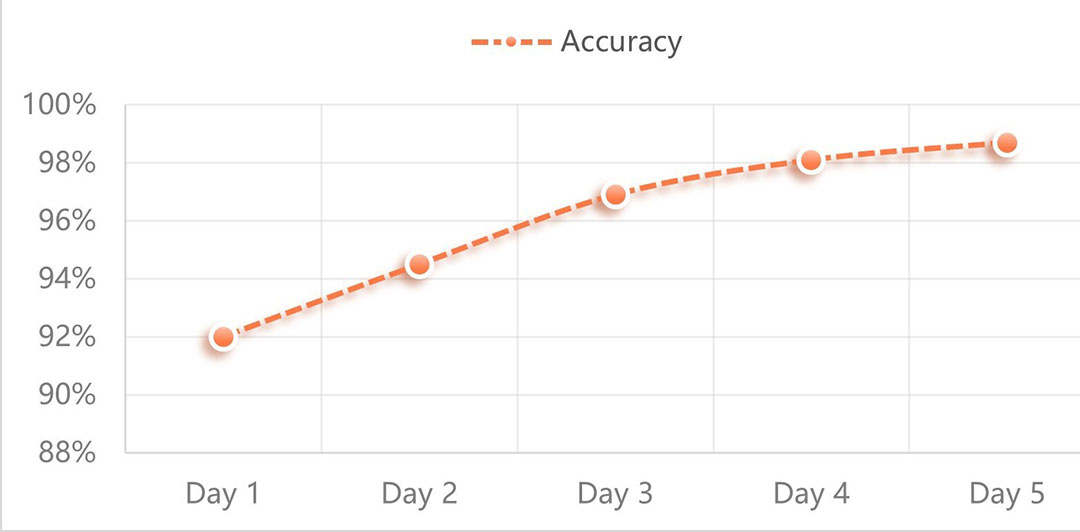

Two modules of the vent sexing machine are available – one is an independent operation unit while the other is a modified version that can be equipped on the production line. Figure 1 shows the evolvement of sexing accuracy during training sessions in one of the biggest hatchery grandparents plants, which is also the typical promotion curve model reflected from Xiashu customers.

Based in Shanghai, Xiashu-tech is devoted to AI applications in poultry science. Besides the vent sexing machine, a feather sexing machine (99% accuracy, 3,000 pcs/h), a duck sexing machine and poultry image weight systems are also products of Xiashu. Poultry image weight system uses deep learning imaging technology to measure poultry weight with high accuracy at 98.5% while identifying male and female poults. This image weighing system works well for both chicken, duck and turkey and now is introduced by customers in Asia.