Part 2: Key performance indicators for poultry processing

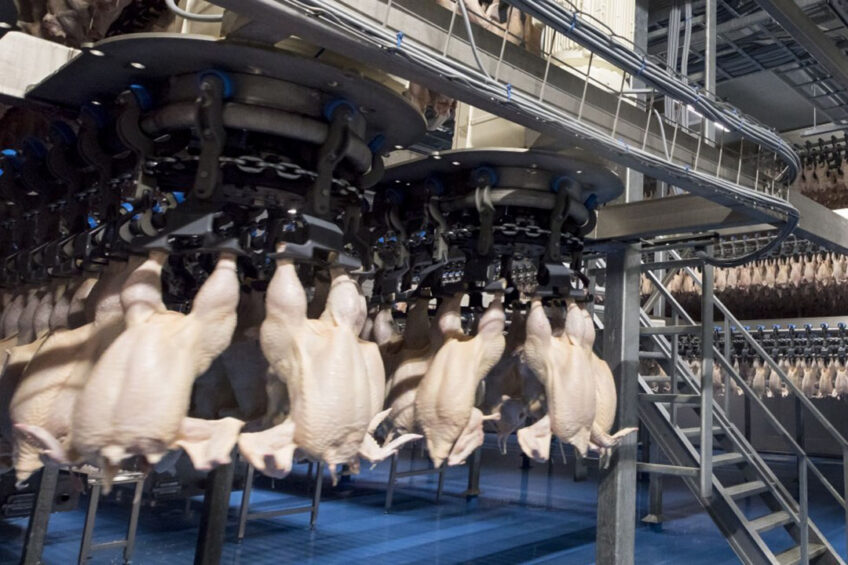

In part 1 of this series, we discussed the importance of managing poultry production performance using key parameters as capability indicators that help producers make better decisions and contribute to operational improvement during slaughter. Through specific training in data collection, and by using consistent statistic methodology while monitoring the results to make permanent improvements in the poultry production process, we have discovered the right strategy.

The meat market is an intense competition field, and commercialisation requirements increase the need to preserve and guarantee the credibility of products and to ensure business sustainability. Credibility and safety are primary concerns.

Considering diseases such as Infectious Bronchitis and Gumboro Disease, the health status of the poultry flocks, and the impacts thereof, require attention in the processing plant. Furthermore, various aspects during meat processing can impact several operational parameters, and, of course, the economic result of operational viability.

Now, in part 2, a closer look at the parameters, associated causes, and their economic impact on the poultry production chain.

Poultry uniformity

The uniformity of poultry flocks will be greatly affected by several factors, including the farm’s facilities, management, nutrition, and sanitary status.

When the broilers are affected by diseases such as Infectious Bronchitis or Gumboro Disease, the flock will not perform to its full potential, and each bird is affected in a different way and to a different degree. This results in uneven growth, and further down the production line, at slaughter and during processing, will impact carcass uniformity, causing slaughter line balance challenges and a reduction in the slaughter line speed. Consequently, processing costs will increase, which will also impact the cost of the final products.

Carcass uniformity and weight

A significant variation in the weight of each broiler will lead to a larger variation between the predicted carcass weight (planned to cover the commercial needs) and the real product obtained and available for the market. Variations in the final weight of chicken meat products could mean that the required carcass weight or cuts are out of the market standard, which will damage the credibility of the brand in the market.

A significant variation in the weight of each broiler will lead to a larger variation between the predicted carcass weight (planned to cover the commercial needs) and the real product obtained and available for the market. Variations in the final weight of chicken meat products could mean that the required carcass weight or cuts are out of the market standard, which will damage the credibility of the brand in the market.See in the picture the range of weight trends to follow a Gaussian or normal distribution. Still, according to the uniformity and coefficient of variation (CV%), the quantity of carcass on the extreme right and left will vary.

The ideal flock’s average live weight CV% accepted under automatic evisceration during slaughter condition must be lower than 8%, assuring ideal balance related to the speed line and also reduced carcass contamination during the sanitary inspection.

Situations A and B illustrate the carcass weight that was obtained during monitoring in the slaughter plant after chilling. The different weight range and their frequency show us in situation A that a larger CV% from female flocks (blue) with limited frequency of heavier carcasses. This reduces the possible range of the carcass and the consequent sales possibility. The orange line illustrates heavier male flocks, offering more carcass weight range possibility opening the sales opportunity.

Situation B illustrates one slaughter day from flocks with a reduced CV%, with a shorter curve considering the carcass weight range (female), concentrating the frequency (yellow line) with very high uniformity, and reducing the sales opportunities. The same characteristics were obtained by evaluating male flocks (blue) with an atypical curve with larger range options.

Carcass yield

In combination with the weight of the cuts that will be impacted by the uniformity, non-uniform carcasses impact industry yields due to ineffective deboning equipment adjustments. The faster the speed of the deboning line, the more imperfect it will be when processing various weights, and the more likely yield will be reduced.

In combination with the weight of the cuts that will be impacted by the uniformity, non-uniform carcasses impact industry yields due to ineffective deboning equipment adjustments. The faster the speed of the deboning line, the more imperfect it will be when processing various weights, and the more likely yield will be reduced.

Sanitary condemnations

Condemnations made due to sanitary reasons will affect operational viability not just because meat is lost from the carcass but because it slows down the operation.

Controlling Infectious Bronchitis Disease

It is known that controlling Infectious Bronchitis Disease is essential to reducing carcass condemnations. In Brazil, a study was conducted in 19 companies where the production of over 100 million broilers was analysed. The benefit of the specific viral strain vaccine to control Infectious Bronchitis is described (Table) in the reduction of sanitary condemnations in slaughterhouses, connecting the benefits of vaccination in the slaughterhouse operations, the economic aspects and the processing performance.

Conclusion

The best operational and economic viability in the slaughter process is characterised by the raw material received considering the live weight and flock uniformity, and the total number of animals available for slaughter as well as their processing conditions (carcass integrity, sanity and slaughter line speed).

References available on request.