Quality-driven in-line distribution of poultry fillets

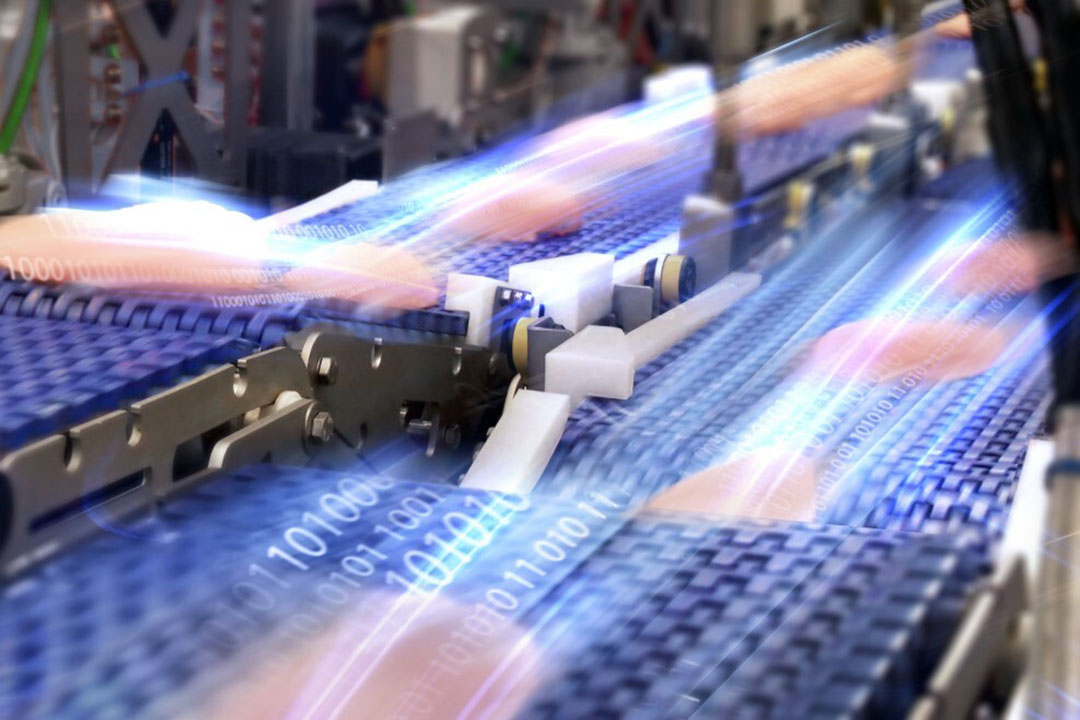

Poultry processors demand the very best utilisation of every single breast fillet. They want to distribute them to the best matching destinations based on weight and quality data. By combining state-of-the-art technology and real-time process data in fillet distribution, Marel’s IRIS FI and Fillet Distributor can get the best out of each fillet. Such a quality-driven in-line logistic distribution on a conveyor belt is a unique solution in the industry.

Processors are looking for ways to distribute all fillet weights and qualities to appropriate streams to utilise maximum product value. Thus far, only one weight range could be picked out for packing, whereas other fillets simply ‘passed by’ on the belt, often destined for bulk purposes. As for fillet quality inspection, only manual assessment after filleting was possible.

Now, Marel allows the assessment and distribution of all quality and weight ranges so that every single fillet can find its best possible destination.

Whereabouts and quality

It is the wish of many poultry processors to know the whereabouts and the quality of each individual product all the way through the plant, not only when it is on the overhead conveyor, but also when it is on a belt conveyor, such as breast fillets. Using Marel’s SensorX, IRIS Fillet Inspector and SystemFlex Distributor conveyors, the grading, tracking and distribution of individual breast fillets on the belt is possible.

There is even more added value when those individual products are given the best possible destinations. This is exactly what Marel’s breast meat value optimisation concept does. It is a logistical concept, feeding multiple in-line end processes based on weight and quality. At all times it achieves the best match between incoming raw material and production orders while maximising throughput and reducing giveaway.

Weighing

A typical breast fillet processing line will feature a deboning system, a trimming station, a bone scanner and a weighing device. By integrating x-ray inspection and weighing functions, Marel’s SensorX is an indispensable system in the fillet process. Alternatively, other in-line weighing devices can also be applied.

Until now, decisions about fillet end destinations were made purely based on weight information. However, QSR and food service companies not only insist on fixed-weight products, but also on their consistent quality. With the implementation of Marel’s fillet value optimisation concept, weight information is enriched with other relevant data such as location and visual quality. In this way, the software gets a stronger dataset to base its decisions on.

Product detectors enable traceability

Normally, once products have been released from the overhead conveyor shackle, their traceability is lost. Individual data, gathered earlier in the process and linked to the shackle, can no longer be tracked, as harvested products such as breast fillets lie randomly on the conveyor belt. Marel’s SystemFlex conveyor intelligence and product detectors along the line are, however, able to locate and trace these products in the process. The system follows product characteristics while the product is on a SystemFlex conveyor. All the time, the system knows the exact whereabouts of the fillet in the process and traceability is maintained.

Visual quality assessment with IRIS FI

The task of IRIS FI is to ensure visual quality assessment of breast fillets after trimming. Using this tool, the system will be able to distribute fillets not only by weight, but also by quality characteristics.

For visual grading of fillets, IRIS FI’s advanced camera delivers an objective, reliable image that shows all possible visual defects. It can detect visual anomalies or defects such as blood spots, skin, fat content or deviant shapes. Detection settings of IRIS FI can be adjusted precisely, from very strict to more tolerant, just what the customer asks for. The area limits can be set for blood and fat independently.

There is no need for manual touching or subjective human judgment, enhancing hygiene, product integrity and food safety, while saving labour. IRIS FI adds visual quality data to the dataset of each individual product which stays with it all the time, enabling quality-driven downstream distribution.

Best destinations

Gathering all data about weight, shape, visual quality and location, and combining it with production orders, Innova software is able to determine the best destination for each individual fillet. If fillet quality is less than optimal, the fillet can be used in a portioned end product and can therefore be assigned to the I-Cut route. If fillet quality is perfect and the fillet is the ideal weight and size for packing whole, it will then be directed to the packing route via RoboBatcher.

Fillet Distributor

In practice, Marel’s Fillet Distributor, featuring intelligent servo-operated SystemFlex conveyor belts, executes the allocation calculated by the software. Its vertically opening and closing belts redirect products of different qualities to different processing streams.

Once the Fillet Distributor has released a fillet to another belt, the position of each measured, weighed and graded fillet stays the same. Product detectors control and recalibrate its position on the belt, so that the system continues to know its exact location, just like the rest of the product data.

The Fillet Distributor allows processors to apply data-driven in-line separation of the streams of different fillet qualities after trimming. An upper belt could lead to a RoboBatcher or another tray packing process, while a lower belt could lead to a marination, shawarma-strip or schnitzel processing line.

Minimise giveaway

Using multiple Distributors, more complex product streams can be configured in the process. With 2 SystemFlex Distributors integrated in the conveyor line, there are 3 possible product streams. The first Distributor can take a certain weight range, or it can take all B-quality products out of the stream for a bulk process. The ‘main product stream’ can go to a RoboBatcher, doing fixed-weight batching, selecting an average breast fillet weight of 250g to assemble 500g trays.

The second Distributor can redirect a third product stream, portioned products such as schnitzels, to be sliced by a SmartSplitter and batched with a Multihead Weigher. All the time, the Innova software looks for the best breast fillets for each product stream to minimise giveaway and assemble optimum product batches.