2022 IPPE: Sustainability, health and antibiotic reduction

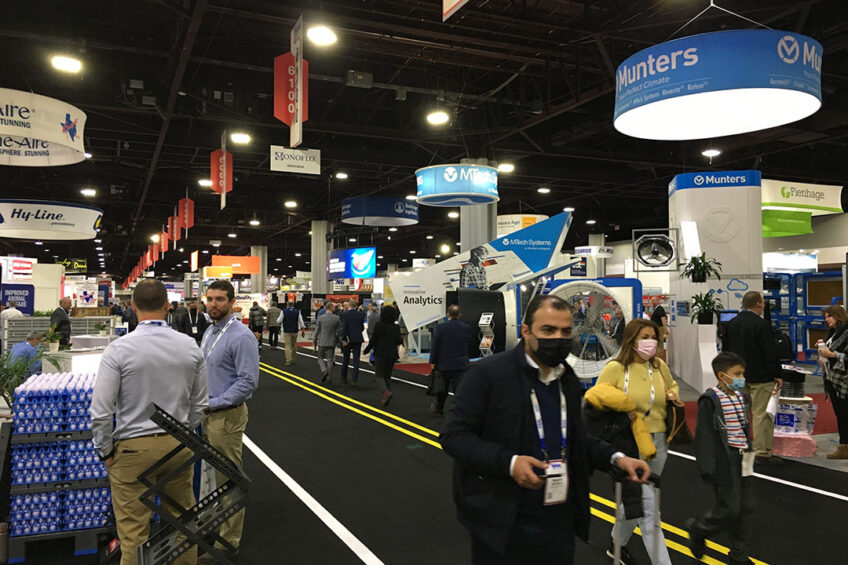

Even with some restrictive Covid-19 measures still in place, the organisers of the IPPE in Atlanta still pushed ahead with their 2022 exhibition, not least because industry participants couldn’t wait to meet in person again. After 2 years of cancellations, there was a lot to talk about. After all, the world and the industry had moved on, even during the pandemic.

At the time of the show, the coronavirus was far from gone. However, the need to meet, discuss and do business outweighed the virus scare which had practically grounded the poultry industry for 2 years, to a large extent at least.

Global attendance despite travel challenges

The 2022 IPPE had almost 22,000 registered attendees from the poultry, meat and animal food industries. Despite the travel challenges, approximately 21% of the registered attendees were international, representing 110 countries and emphasising the worldwide reach of the show. Poultry World took the opportunity to talk to industry decision-makers to get a better idea of the dynamics currently influencing future decisions in the US and heard that for many exhibitors and visitors alike, sustainability, health and antibiotic reduction are high on their list of priorities. Here follows a snapshot.

Controlling salmonella

Rick Phillips, head of US poultry vets and director of poultry professional services veterinarians at Boehringer Ingelheim told us: “In the last few years we, the industry and the controlling bodies of the government have made huge strides in improving diagnostics and testing when it comes to salmonella. And that has exposed new challenges. As you know, in the US, potential salmonella issues are solved at the processing plant by carcass rinsing instead of preventing the bug in the first place in the poultry production chain. That seemed to work well for us, but improved testing methods painted another picture.”

Salmonella presence despite rinsing

Phillips added that in the past, the carcasses tested negative after rinsing, but those negative tests were – to some extent – caused by the decontaminants producing false-negative results. “With the new tests, we see salmonella despite the rinsing, and that is a challenge. Luckily these new tests can help the industry as well, simply by using them in the field and tracking salmonella there,” he said.

Getting ahead of the problem

It all comes down to the mindset, adds Phillips, whether we do or do not want to know where the bug is. “If we do want to know, then we can take measures to get rid of it. That is the path that we at Boehringer Ingelheim want to take. The industry has to understand that it has to get ahead of the problem. We want to be as close as possible to our customer, we want to test, track and tackle salmonella on the farm with commercial and customised vaccines. Information is knowledge and we know the technology is there not only to test but also to combat salmonella. Through vaccines but also via improved farming practices and stockmanship. Yes, we have these controlled-climate houses but growing birds is not an automated process. To make a real difference we need a hands-on approach at every step of production, for salmonella control and a host of other issues as well.”

Antibiotic reduction

Dan Jaffee, president and chief executive officer Amlan said: “Since the last IPPE 2 years ago, we have seen antibiotic-free broiler production in the US grow from 30% to 50% now. This trend will accelerate over the next couple of years because it is not only necessary to prevent antimicrobial resistance, but because there is also a ‘green’ premium nowadays. Consumers demand clean food and are willing to pay for that. Economically it also makes perfect sense to produce NAE [no anitiotics ever] birds. The process of reducing antibiotics is not as straightforward as it seems but luckily we can learn from the 30 years of experience our European colleagues have. One lesson here is that if you stop the use of antibiotics, you need to develop new tools for your toolbox. That is why we have invested heavily in R&D to develop a natural non-antibiotic solution that adsorbs and absorbs toxins in the gut and can thus prevent disease and the need for antibiotic use. As straightforward as this sounds, it encompasses a paradigm shift in our industry.”

Sustainability

Christie Chavis, vice president animal nutrition and health performance solutions at DSM reported: “According to a recent study, feed additives can reduce the environmental footprint of animal protein production by 10% and that’s where we see a lot of potential for our Performance Solutions + Biomin portfolio to contribute to more sustainable animal protein. At DSM Animal Nutrition and Health we continue to highlight the need for sustainable farming to meet the demands of an ever-growing global population.

“Our approach with ‘We Make it Possible’ is to address some of the biggest issues within the animal protein industry by leveraging scientific innovation and partnering with actors across the feed and food value chain. Moreover, progress relies on credible and robust measurement — which is why we work with multiple stakeholders, customers and leading experts to conduct environmental life cycle assessments of their farms.

“Many of the topics in the sustainability discussion are interlinked. Feed represents anywhere from 50% to 70% of the total costs of livestock rearing and accounts for 50% to 80% of the environmental footprint of animal protein products. In the current context in which producers are facing higher feed ingredient costs, it’s only logical to look for strategies that will improve efficiency – by including feed enzymes, mycotoxin de-activators and eubiotics in our portfolio — that will deliver not just higher output or feed cost savings to underpin profitability but also support better animal health and welfare, and reduce environmental emissions from farms.

“Having been at IPPE I enjoyed the energy, connection and emotions with in-person events. However, our working environments have evolved into a hybrid approach. We aim to leverage the best digital tools and offline interactions to serve our customers the way they want to be served. Digital tools have helped us to communicate with existing and potential customers, and we have continued to develop our award-winning online customer portal to enhance the quality of our service delivery. In-person sessions are great for understanding our customers, co-creating innovations and for developing robust face-to-face partnerships, including trials, knowledge exchange and networking. We hope that circumstances will allow us to continue to step up this activity, wherever possible while safeguarding the safety of our clients, employees, suppliers and stakeholders.”