Tackling carcass contamination at the source

The poultry industry has been doing phenomenal work over the past few decades producing ever increasing volumes of healthy and affordable protein, thus contributing to improvements in global consumer diets and mitigating hunger in the poorest areas of the world as well. One of the most important challenges the industry has been faced with, which will also determine its reputation, answers by the name of food safety.

The Codex Alimentarius Commission defines food safety as “the assurance that food will not cause harm to the consumer when it is prepared and/or eaten according to its intended use”. According to World health Organization (WHO), foodborne diseases threaten international public health security to a point that each day millions of people become ill and thousands die from a preventable foodborne disease. More than 200 diseases are transmitted through food, and diarrheal diseases alone – a considerable proportion of which is foodborne – responds for 2.2 million deaths around the world every year, mostly of them occurring in poor countries. Foodborne diseases are, nevertheless, not limited to developing countries, nor are they restricted to diarrheal diseases, says WHO. Despite governmental attempts to improve the food supply safety, the occurrence of foodborne disease remains a significant health issue in both developed and developing countries, but the full extent of the burden and cost of unsafe food are currently unknown. This information become necessary, however, to guide food safety policy-making and provide a baseline for monitoring and impact assessment of food safety measures. WHO teaches that even though food contamination can occur at any stage of the food production chain, foods improperly prepared or handled at home or in food service establishments are responsible for a high proportion of foodborne disease cases. Yet education of food handlers and consumers to raise awareness of food safety risks is therefore, essential to prevent foodborne diseases and ensure better health. This certainly is a hard task to accomplish in its wholeness. Consequently, despite the continuous governmental educational efforts, it is recognised that the broad margin for poor food-handling practices, and the resulting potential occurrence of foodborne disease outbreaks, still exists at market level. Nevertheless, it is to compensate for these deficiencies, therefore protecting consumer health from potential foodborne outbreaks, that the food safety measuring parameters applied to food production become more stringent every day.

Food safety

In the chicken industry, the concern about food safety starts before the birds arrive to the plant, by carefully designing and managing a proper feed-withdrawal program. To achieve an optimal gastrointestinal system emptying, therefore reducing the risk of faecal contamination along the processing chain, broilers must be off-feed for a period of 8 to 12 hours prior to slaughtering. Water must be available up until the moment catching starts, as to enhance the feed transit and excretion. Properly designed feed withdrawal

programs take into consideration the broilers’ physiological responses to

day and night catching, and hot and cold weather and the impact of feed restriction programs, as well. In hot climate, companies shower the live loads from top down, for one minute or two, upon their arrival to the plant and before they head to the holding shed. It aims at cooling birds down to reduce the risk of in-plant mortality, a practice recommendable under the animal welfare perspective, but perhaps not likely recommendable under the food safety standpoint. As most of the faeces excreted along the journey rest onto the crates’ floor, the water from the shower may easily liquefy and sprinkle it all over the live load. The liquefied faeces spillage attached to the feathers will be further carried on to the scalder, therefore increasing the water contamination. Carcass scrubbers are gaining an important momentum as an effective, physical intervention in the reduction of the amount of faeces birds carry

on attached to their outer surface – cloacae and feet – as they arrive at plant. Rotating brushes in combination with water and sanitisers gently washes the carcasses’ faeces load down before they enter the scalder. A scrubber available at market place uses antimicrobial-impregnated bristles

to eliminate the cross-contamination

during the process.

Water scalding

Water scalding predominates in the poultry industry around the world. As an important in-plant cross-contamination vector, it deserves a proper management approach, whose priority is to reduce the level of contamination in the water. In Brazil, where nothing but water is allowed to cope with the water bacterial load, plants must fully renovate the scalder water during the operation hours. For a scalder with 160,000 liters of volume and operating for two shifts, for instance, it means 10,000 liters of make-up water is added to the scalder per hour. In US plants, 0.5 liter/hour of make-up water per carcass is required and chemical interventions to reduce the water bacterial load, which are all-natural, organic compounds-based formulations, with no impact on the products’ wholesomeness, are allowed. In other countries practices can be officially regulated or not. Likely important for the contamination is the scalding temperature. Given some countries prefer white-skinned birds while others yellow-skinned birds, water temperature must be set properly as to achieve the final desired carcasses outlook. Research shows that the higher temperatures required by hard-scalded, white skinned birds have a higher rate of kill of the bacterial load than the low water temperature required by soft-scalded, yellow-skinned carcasses. To exemplify, in an experiment Salmonella typhimurium and C. jejuni were inoculated in scalding water to examine the effects of scalding temperature (50, 55, and 60°C) associated with the ages of scalding water (0 and 10 h), on bacterial survival or death. After scalding at 50 and 60°C, the reductions of C. jejuni were 1.5 and 6.2 log CFU/ml in water and <1 and >2 log CFU/cm2 on chicken skins; the reductions of Salmonella typhimurium were <0.5 and >5.5 log CFU/ml in water and <0.5 and >2 log CFU/cm2 on skins, respectively. The age of scalding water did not significantly (P >0.05) affect bacterial heat sensitivity. Last, but not least, the water and carcasses flows into scalder affect significantly the water microbiological profile. In single-tank scalders, water and excreta rinsed from the carcasses moves down the scalder alongside the carcasses. In counter-current scalders, where carcasses and water move in opposite ways, the water flow washes birds’ contamination off as they travel through ever-cleaner water towards the exit. Best, though, are the multi-stage scalders, a proven effective tool in reducing the bacterial load into water. Experiments demonstrate that the reduction in the pathogens counting between tanks one and three, of a three-tank scalder, can be as expressive as 2.5 log10, for coliforms and E. coli. For Salmonella, positive samples in tank three can be as low as 10% of the total samples, what indicates that most bacteria removed from carcasses during scalding are washed off during the early part of scalding. Consistent reports of sharply declining numbers of bacteria suspended in the water in successive tanks of multiple-tank scalders indicate that opportunities for cross-contamination during scalding are probably being minimised by the multiple-tank design, as compared to single-tank designs. Despite all the previous efforts, birds leaving the scalder drag along a

substantial amount of contaminants entrapped in the wet feathers. To

mitigate the impact of this contamination along the defeathering process and further down the line, dip tanks or high-pressure outside washer, with or without the addition of chemicals to the water, emerge as a promising physical intervention in the reduction of contamination levels of the post-scald carcasses as indicated by some research works.

Cross-contamination problems

Pickers present a serious cross-contamination problem as demonstrated in a study where a carcass marked with a specific micro-organism had this

marker dispersed all over 200 other carcasses during defeathering. Additionally, faecal material is squeezed from the carcasses by the picking fingers mechanical action and pressure, and subsequent carcasses are exposed to this faecal material as they are rubbed by the same contaminated fingers. Moreover, the pressure fingers exert onto the carcasses pokes the present microorganisms into the superficial skin’s layer, making removal harder, or impossible, further down the line. In this case, a properly designed and managed feed withdrawal program can contribute to reducing, but not eliminating, the faeces spillage along the picking line. Efforts have been made to control

this problem by adding, for instance, antimicrobial compounds to the

rubber picker fingers. However, there was little evidence of this approach’s efficacy. The use of adequate water flow, chlorination and proper post-operation cleansing and disinfection can contribute positively to decreasing the level of contamination during the defeathering.

Evisceration department

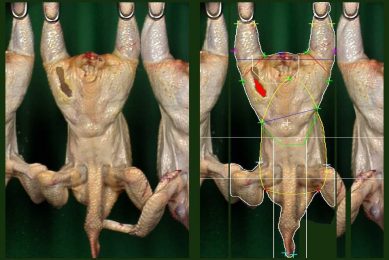

The evisceration department is another area of risk for carcass contamination. As hand-eviscerated carcasses are less likely to be contaminated than its automatically eviscerated counter-parts, this last one only will be addressed here. Flock uniformity plays a major role in the overall performance of the automatic evisceration line and, therefore, may contribute to either increasing or decreasing the degree of faecal and bile contamination during operations. A dependable, well-planned maintenance work in conjunction with continuous, prompt operation of the evisceration line along the operation hours are of utmost importance in the context of this department. Together, they are responsible for extending the life of the equipment and guaranteeing the optimal operational performance, therefore minimising damages to carcasses – like tore intestines, for instance, and its consequent risks – and losses associated with the salvage of contaminated, downgrade carcasses.

Carcass contamination

The risk of carcasses contamination is inherent to the vent cutter, opener and eviscerator. The first prerequisite to minimise the risk of faeces spillage is having in place a good feed withdrawal program to guarantee the birds have emptied their intestines prior to arrival at the plant. Proper adjustment of the vent cutter height and guide bars, as to cope

gently with the carcasses in process, eases their accommodation to the modules and guarantees a smooth, low-risk performance. Monitor the incidence of tore intestines and assure the vent is properly displaced and is not causing faeces spillage onto the carcasses, otherwise adjust the machine and/or notify the field personnel about the presence of faeces in the intestines and rectum. Keep blades sharp for a precise clean cut, and water nozzles properly adjusted and unobstructed for optimal carcass washing. The opener must deliver properly opened carcasses, the prerequisite for a further easy, damage-free viscera extraction. Therefore, keep blades the sharpest possible and guarantee a natural, gentle carcass coupling to the modules by adjusting the height and guide bars properly. Too much pressure on the breast could force viscera package up, nearing it dangerously to the abdominal skin and the displacing blade. Have an eye always on the length and consistency of the opening – have in mind it also enhances the removal of internal contaminants and the carcass cooling during the chilling process, as well – and on the occurrence of tore intestines. Respond appropriately and promptly in case of either deviation. Keep water nozzles unclogged and properly set for optimal hygiene along the hours. A properly adjusted eviscerator should not pull out the viscera package from the carcasses, but just exteriorise it, instead, therefore preventing the package from falling down, liver and gall bladder from damages and, mostly, intestines from rupturing. To be successful, set the machine properly to the carcasses in process, monitor the operation, and in case of any deviation, act back promptly and appropriately.

Inside-outside washer

The role played by the final inside-outside washer should never be minimised or neglected in the context of the evisceration department. Even though a simple piece of equipment, it is a powerful tool. A properly set washer – appropriate water pressure finely adjusted, unobstructed nozzles and use of chemicals – can remove a significant amount of internal and external contaminants from the carcasses blood, fat and faeces – during its short cycle time. By reducing the organic load transferred into the pre- and chiller by the post-evisceration carcasses, the final washer preserves the biocidal action of the chlorine, which, otherwise, would be inactivated in the presence of organic matter, therefore enhancing the so important decontamination capabilities of the chilling operation.

Tackling carcass contamination is not a simple task. To be successful, it must start in the first steps of the processing chain and perpetuate through until the end. Besides, it requires a multi-factorial management approach, a personalised set of measures and actions specific for every single plant and/or process and the unconditional commitment of both field and plant personnel to be successful.

References available on request. Article published in World Poultry issue 29.2