Automatic lameness detection using smart broiler farming

Lameness is a major production disease affecting broiler welfare and profitability. Although lameness is a prevalent condition in broiler production systems, its identification can be unreliable due to lack of individual animal observation for gait and posture abnormalities and standard evaluation criteria. Automatic lameness detection adds a valuable tool in tracking bird condition.

To prevent financial losses and welfare problems, early and accurate lameness detection and treatment is essential. The most common method to evaluate lameness is visual scoring which is easy to do and cheap to implement but has disadvantages, such as the time and labour involved, plus it is prone to observer error due to the limitations of human visual perception. Therefore, automated lameness detection methods that do not rely on the human visual capacity and which are not subjective may offer a more accurate method of lameness detection.

Lameness in broilers

Lameness is defined as a deviation from the normal gait caused by lesions, disease and other factors, such as genetics, nutrition, housing systems and management practices. However, the term lameness is used for a broad range of conditions, including foot and leg problems, conformational deficiencies, lameness, unsoundness, injuries and abscesses on the limbs.

Lameness may be episodic and, because multiple joints may be affected, it can shift between legs. Due to its association with pain, discomfort, reduced mobility and reduced ability to cope with the environment, lameness is regarded as an indicator of poor welfare. Broiler lameness prevalence ranges from 14.1% to 57%.

Direct lameness costs include increased workload, medical treatment, reduced productive and reproductive performance, higher culling rate and increased production costs. It is estimated that lameness costs the US poultry industry approximately US$ 150 million a year.

Smart broiler farming

In modern livestock production systems, farmers need reliable and affordable technologies to assist them with daily management tasks which guarantee accurate and continuous individual animal monitoring.

The application of engineering techniques in broiler farming to monitor, model and manage animal production aims to increase the farmer’s ability to maintain contact with individual animals as broiler production intensifies, and to prevent health, welfare and management issues. Using smart broiler farming a large volume of data can be collected in a short period of time which can be used improve the accuracy of lameness prediction.

Visual lameness evaluation

Visual lameness scoring systems in broilers use a 5-scale scoring method in which score 0 = walks normally, score 1= detectable but unidentifiable gait abnormality, score 2 = identifiable gait abnormality that has little impact on overall function, score 3 = identifiable abnormality which impairs function, score 4 = severe function impairment but still capable of walking, and score 5 = complete lameness.

Need for automatic lameness detection

Early and accurate lameness detection and treatment is essential to avoid economic losses and welfare problems. It is also possible that animals may instinctively hide lameness as a self-preservation mechanism until it becomes severe making lameness assessment during the early stages difficult when using a visual scoring method.

Additionally, producers that look at their animals every day may under identify the number of lame animals and only notice severely lame animals. Lameness under-representation by producers results in fewer lame animals receiving veterinary treatment and thus a greater prevalence of lameness on the farm.

Automatic lameness detection

Various scientific approaches have been used to develop a fully automated and continual lameness detection system based on kinematic analysis and behavioural change detection using sensors, data and image analysis. Kinematic analysis measures the movement geometry, without considering causal forces and calculates different gait aspects, such as stride length, stance and swing duration.

Since lameness can affect injured animal behaviour, parameters such as uneven weight distribution between the legs, greater weight shifting between legs while standing, increased lying times and bouts, reduced walking speed, along with changes in feeding behaviour and activity, can be used as lameness indicators. Sensors, such as cameras and a force platform, can be used to detect behavioural changes and lameness.

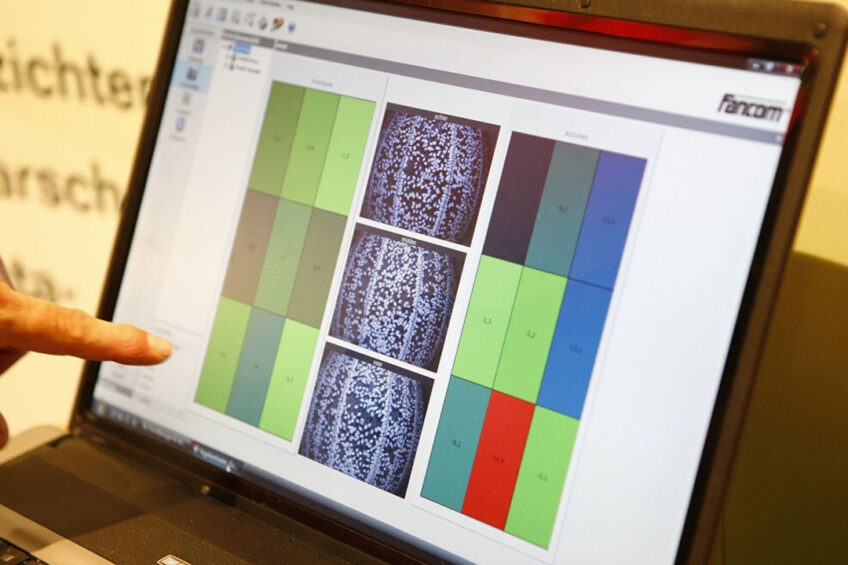

Data and image analysis techniques can be used to evaluate, process and extract useful information from images and improve image quality while reducing undesirable effects, such as noise and blurriness by enhancing resolution. The information obtained from an image using data and image analysis might include geometrical features, like dimensions, angles, shapes, density, and contrast features, such as darker or lighter regions; plus material related features such as rough or smooth surfaces.

Sensors applied in studies

In 2010, Nass and colleagues assessed locomotion deficiencies in broiler chicken by analysing the vertical peak force on both feet while walking on the force platform. Peak force asymmetry was found for each foot, independent of age or gait score.

In 2017, Aydin and Silvera and colleagues indicated that a 3-dimensional camera with a depth sensor can be used as a non-invasive and non-intrusive tool for automatic broiler lameness assessment. They used the number of lying events, latency to lie down, speed, step frequency, step length, lateral body oscillation and daily activity as indicators of lameness.

In 2018, Naas and colleagues developed an algorithm and software to analyse broiler gait score videos. Using the developed software, lameness can be detected in broilers under commercial rearing conditions as the displacement velocity can be easily measured. In 2018, Van Hartem and colleagues showed that a camera-based monitoring tool for flock behaviour analysis can potentially warn the poultry farmer of possible gait problems in a commercial farm setting.

Valuable tool

Smart broiler farming increases the farmer’s ability to maintain contact with individual animals as broiler production continues to intensify. With smart broiler farming a large volume of data can be collected in short period of time which can be used to improve the prediction accuracy of lameness.

A digital camera-based monitoring tool is accurate, inexpensive and reliable. However, further data capture is needed to standardise animal tracking. Force platforms have good potential to support future objective research in lameness, but low specificity can occur with handling alone.

However, more measurements and especially delicate software are needed to create a robust system for the farm environment. Similarly, to develop a sound lameness detection system, data from different sources will need to be combined using a multivariate approach.