Biomarkers and machine learning give early warning system for poultry producers

An early-warning system based on blood biomarkers and big data techniques gives poultry producers greater insight into what happens in birds, giving them enough time to address issues before they cause significant losses. DSM’s senior director of precision nutrition and health, Scott Cavey, explains.

The main challenge at highly efficient poultry production facilities is finding ways to improve an already smoothly-running operation. The main levers for improving livability in an already efficient system include better bone health by focusing on calcium, phosphorus and vitamin D; optimal acid/base balance for bird health; mitigating the effects of coccidiosis; modulating immune response related to disease challenges; managing electrolyte balance related to heat stress and enhancing animal welfare conditions.

“Using big data analytics can help to uncover opportunities for productivity improvement and loss prevention,” says Cavey, who is closely involved in the Verax project in which a setup for on-farm blood tests was developed that are analysed and compared with huge datasets using machine learning.

Verax is an early-warning system using blood-based biomarker analysis that can uncover a host of hidden health and nutritional challenges, including coccidiosis, necrotic enteritis, microscopic E. maxima, welfare, heat stress, immunity response, as well as calcium or phosphorus deficiencies. With high input prices and calls for greater sustainability, the need for efficiency improvements has never been greater. Improving livability by 0.5% for a broiler complex producing 1 million birds a week would result in additional annual revenue of US$1.2 million (assuming 6.5 lb/2.9 kg birds at November 2022 prices in North America), along with labour cost savings and a lower environmental footprint.

Next frontier in productivity

The agriculture sector notoriously lags behind other industries when it comes to the adoption of digital technologies. For decades, the practice of poultry management has been largely reliant on subjective visual assessments of birds. Now, the emergence of precision livestock farming tools that use data-aided decision-making and automation offers new opportunities to further improve productivity. Cavey: “Real-time monitoring is one application of technology that draws upon audio and visual cues to supplement human visual assessment and is starting to gain traction.”

Early-warning system

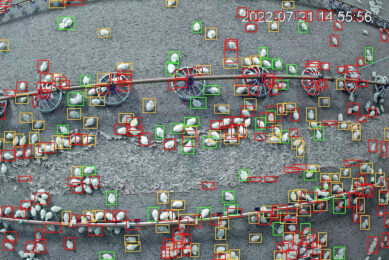

“Another application is to predict potential problems before they arise,” Cavey knows. One such early-warning system successfully deployed in commercial broiler complexes relies on blood-based biomarkers to provide a detailed picture of animal health at the cellular level where disease begins. Blood samples collected from birds on site are analysed with machine learning software, then compared against benchmark industry data and peer-reviewed research using statistical modelling and machine learning to predict potential performance issues and generate suggestions for corrective action within a few hours.

“Ideally, one would process the blood work of 100 birds per house once every quarter, so you create a baseline from which you can dig deeply into problems when or even before they arise,” the specialist explains.

By focusing on the bird’s biological processes, insights from an analysis of blood biomarkers can indicate the likely incidence of disease or nutritional deficiency without the need for posting or waiting until birds become symptomatic. That advance warning means producers have time to implement preventive and corrective measures early on, supporting production efficiency, animal health, welfare and sustainability.

Coccidiosis and pre-disposing factors

Coccidiosis is an intestinal disease that costs the global industry more than US$ 3 billion in economic losses due to mortality, reduced body weight, plus the expenses related to preventive and therapeutic control while also predisposing birds to necrotic enteritis. An early-warning system has value for producers if the insights generated are sufficiently granular and accurate to be implemented. Here we looked at two models, one for Eimeiria maxima and the other for E. acervulina, to illustrate the granularity and accuracy of such a system.

Cavey: “Researchers have validated a model that provides early prediction of coccidiosis and isolates the different stages of severity of enteritis within each farm up to 8 days before it is visible. This advance warning can translate into a significant financial benefit for the farmer and a better overall health and welfare status for the birds”. The specialist continues: “For the blood work, normally no birds have to be sacrificed. That said, for the coccidiosis status, it is wise to work together with the veterinarian and compare the blood work with the results of a necropsy.”

E. acervulina is a common protozoal parasite in poultry and one of the parasites that cause coccidiosis. “Using an algorithm-based model, our team aided a poultry integration in EMEA to predict the likely rate of infection of flocks based on data from blood biomarkers within 2-3% of the veterinary diagnosis,” says Cavey. Table 1 illustrates how such an early-warning system can help reduce the time to diagnose certain health challenges.

Getting to the root cause faster

“Eliminating guesswork helps get to a resolution more quickly. For example, often, when we find companies with high DOAs (dead on arrival) at the processor, the assumed cause is heat stress. However, using a broad number of biomarkers, we detected hypoglycemia in those flocks. This insight shifts our customers’ attention away from further investments in solutions such as installing fans and shade, and instead, they investigate grind size in feed and feed intake variances. Pinpointing the real issue and taking appropriate action saves producers considerable time and money. I have seen customers who were in awe after sharing our results,” states Cavey.

Monitoring immune response

By looking at immune response factors such as the movement of albumin and globulin proteins, blood biomarker analysis can indirectly reveal the impact of vaccines on production. Cavey: “In one case, a customer observed their robustly designed vaccination programme was not delivering sufficient immune response in the birds. Further investigation uncovered that the vaccine had been frozen, contrary to the prescribed storage and handling guidelines, impairing vaccine efficacy.”

Blood biomarker analysis identified which farms were given the properly or improperly stored batches of the vaccine. “The customer could then take steps to mitigate the issue, preventing further production losses.”

Unlocking greater production efficiency

For the poultry industry, blood biomarker-based analysis has the potential to improve production efficiency and usher in a new framework for bird monitoring, assessment and decision-making that will redefine industry best practices (Table 2). Reducing food loss and waste by leveraging new machine learning technology can potentially add to producer profitability, promote bird welfare and shrink the environmental footprint of poultry production.