CT scan useful for inspecting poultry bone fractures

Animal welfare officers at slaughterhouses are tasked with identifying and recording bone fractures in poultry. According to research by the Institute for Risk Assessment Sciences, CT scans can provide a useful addition to this visual inspection.

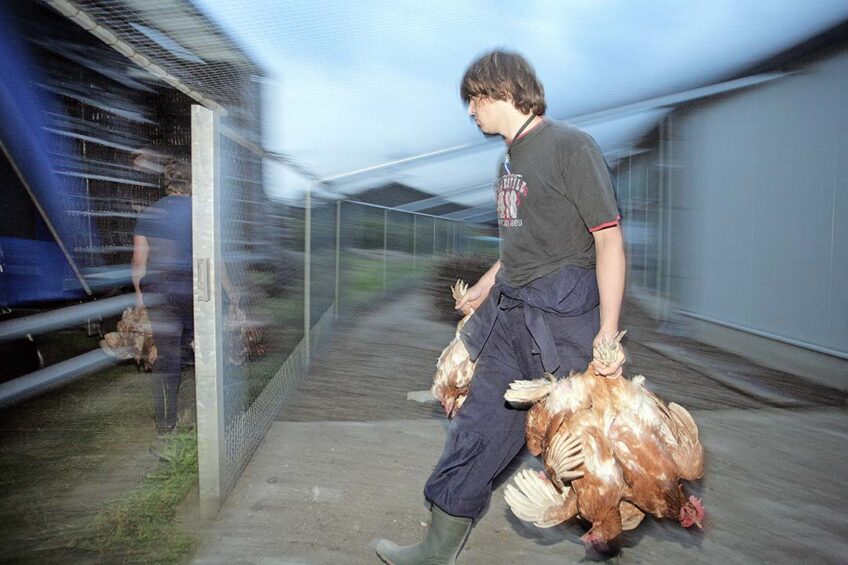

European legislation requires that slaughterhouses monitor animal welfare themselves. However, how this should be done is determined by national governments. Until recently, the Netherlands Food and Consumer Product Safety Authority (NVWA) used a threshold value of 2% per flock for injuries observed at poultry slaughterhouses. However, since 1 January of this year, NVWA has started fining companies that scored above 1% injuries per flock (see box below: Enforcement limit halved to 1%). If the limit is exceeded, both the poultry farmer and the catch team can be fined.

Broilers are prone to bone fractures, which are not always noticed upon inspection. Observations are subjective: no 2 people always reach the same conclusion. In fact, no individual always makes the same decision because no one is equally sharp at all hours of the day. The aim of the study by Len Lipman and fellow researchers from the Institute for Risk Assessment Sciences – a research institute in the faculties of Veterinary Medicine and Medicine at the University of Utrecht – was to monitor this in a more objective manner. They looked into the combination of CT scans and visual inspection.

Experiment

A limited number of samples was analysed for the experiment: 83 wings and 60 legs from 143 Ross 308 chickens. First, an animal welfare officer assessed whether there were bone fractures or not, and whether they originated before or after death. Bone fractures before slaughter usually occur during catching, loading, transport and handling at the slaughterhouse. After death, these are caused by slaughter equipment that does not function optimally, among other things.

Parts with bone fractures that occurred pre or post mortem are no longer suitable for human consumption. However, when the injury occurred makes a big difference to animal welfare, as animals feel pain while alive.

After the assessment by the welfare officer, CT scans were done where 8-12 wings and 3-5 legs of the broiler chickens could be scanned simultaneously. In addition, photos were taken. In the study these were subject to visual inspection on the slaughter line. Scans and photographs were then independently assessed by 3 veterinarians using the classification provided by the animal welfare officer.

Where injury was seen, the veterinarians determined whether it occurred before or after death. The assessment took place in 3 rounds: solely on the basis of the CT scans, using both CT scans and photographs, and solely on the basis of the photographs. The rounds were conducted 1-7 months apart. The veterinarians were therefore not influenced by their own previous assessment. The assessment was then compared with that of the animal welfare officer.

The similarities appeared to be greatest when scans and photos were combined. The assessment based solely on the CT scans was relatively reliable in detecting fractures, but less suitable for determining when they had occurred. Visual inspection, in the form of photographs in the experiment, was precisely the opposite: the cause of the injury could be determined in this way but it was not an effective method for detecting fractures.

The scientists therefore concluded that visual supervision and CT scans will lead to more reliable inspection results. The slaughterhouse can also use the data to adjust the equipment and thus further reduce post-mortem bone fractures in broilers. The researchers state in their online article in the scientific journal Poultry Science that scans in combination with visual inspection can also offer benefits in the field of food safety and food quality.

Camera systems

In the experiment, the CT scans were analysed by veterinarians but artificial intelligence could also be used for this. The objectivity of visual inspection by the human eye can be further enhanced by using camera systems. These are cheaper than scanning equipment and easier to use, given that no protective measures against X-rays need to be taken, as with CT scans. However, the researchers also see a future for scans. New developments in CT scan technology may help to eliminate the disadvantages.