Overcoming the challenges of xylanase inhibitors in poultry

Scientific understanding of xylanase inhibitors (XI) and their impact on animal nutrition has grown significantly. Xylanase, a crucial enzyme used to enhance nutrient availability in feed, can face challenges from XI present in cereal grains. This article explores the evolution of plant protection mechanisms, the economic impact of XI and the development of a novel xylanase, Axxess XY, resistant to these inhibitors.

Xylanase inhibitors are a classic example of the evolutionary development of protection mechanisms by cereal plants against pathogens. Microorganisms, such as fungal pathogens, involve the degradation of xylan as one of the mechanisms in pathogenesis.

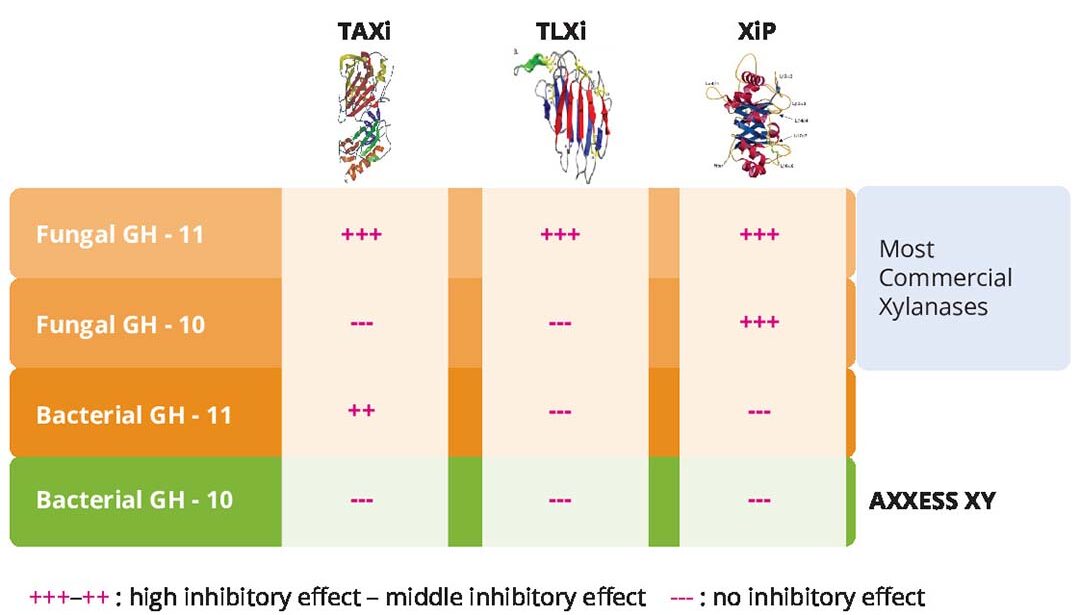

There are also other mechanisms by which microorganism-produced xylanases affect plants. To protect themselves, plants evolved xylanase inhibitors to prevent the activities of xylanases. XI are plant cell wall proteins broadly distributed in monocots. There are 3 classes of XI with different structures and inhibition specificities: Triticum aestivum xylanase inhibitors (TAXI), xylanase inhibitor proteins (XIP) and thaumatin-like xylanase inhibitors (TLXI).

Economic impact

In animal nutrition, xylanases are widely used in diets containing cereal grains and other plant materials to achieve a greater availability of nutrients. The inhibitory activity of XI prevents this positive effect of the enzymes and, therefore, makes them economically relevant.

Studies have reported that higher levels of XI negatively impact broiler performance. For example, in one study broilers fed with grains of a cultivar with high inhibitory activity showed a 7% lower weight on day 14 than broilers fed with grains of a cultivar with less inhibitory activity. Another study by Ponte and others also concluded that durum wheat xylanase inhibitors reduced the activity of exogenous xylanase added to broiler diets.

Withstanding high temperatures

Even though XI can impact the performance of exogenous xylanase in different ways, scant attention was paid to the reduction of xylanase’s susceptibility to xylanase inhibitors during the development of xylanase in recent decades. Firstly, the issue was ignored mainly due to the assumption that XI are denatured or destroyed during pelleting processes. However, Smeets and others showed that XIs could withstand significant temperature challenges. They demonstrated that after exposing wheat to pelleting temperatures of 80°C, 85°C, 92°C, and 95°C, the recovery of inhibitory activity was still 99%, 100%, 75% and 54%, respectively.

Other studies also confirmed that conditioning feed at 70-90°C for 30 seconds, followed by pelleting, had little effect on XI activity in the tested feed, showing that xylanase inhibitors are very likely present in most xylanase-supplemented feeds given to animals.

Multiple feed ingredients affected

After first reports of the presence of xylanase inhibitors in wheat by Debyser and others, XI were also found in other cereal grains (corn, rice and sorghum, etc.) and their involvement in xylanase inhibition and plant defence has been established by several reports. In most countries outside Europe, exogenous xylanase is used not only in wheat but also in corn-based diets.

Besides broiler feeds, other animal feeds, such as layer or swine feed being part of more mixed-grain diets, are also susceptible to the inhibitory activity of XI. Nowadays, the situation is getting worse with increasing raw material prices and nutritionists tending to use other feed ingredients and locally-produced cereals. They need a xylanase which is resistant to xylanase inhibitors.

Xylanase resistance to XI is crucial

To prevent xylanases from losing their effect due to the presence of xylanase inhibitors, the resistance of new-generation xylanases to these substances is paramount in the development process, including enzyme discovery and engineering. Over the past 25 years, scientists have learned much about XI-encoding genes and discovered how xylanase inhibitors can block microbial xylanases.

Additionally, there has been a significant increase in understanding the structural aspects of the interaction between xylanases and XI, mainly how xylanase inhibitors interact with specific xylanases from fungi or bacteria and those in the GH10 or GH11 family.

With this understanding, a new generation xylanase, Axxess XY, was developed. Besides showing the essential characteristics of intrinsic thermostability and versatile activity on both soluble and insoluble arabinoxylan, it is resistant to xylanase inhibitors. Axxess XY takes xylanase application in animal feeds to the next level.

Outperforming the market

Recent scientific developments and internal research can be summarised as follows. Its high resistance to xylanase inhibitors is one of the reasons why a novel xylanase with bacterial origins and from the GH-10 family was chosen for Axxess XY.

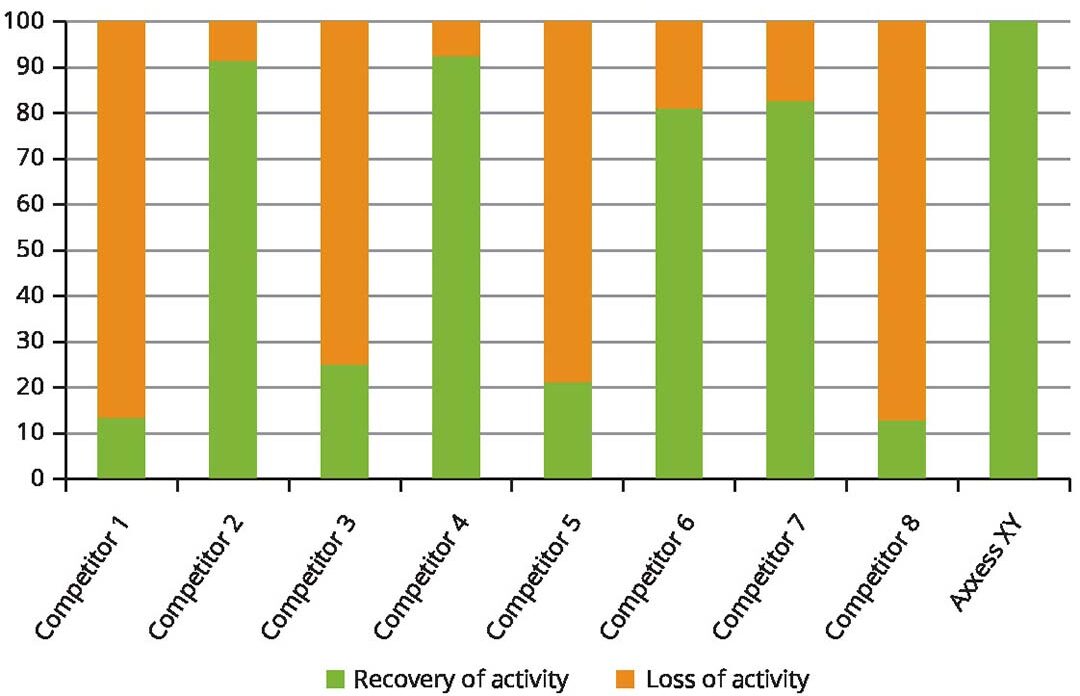

EW Nutrition innovation, together with its research partners, carried out an interesting benchmark comparison between xylanases that are commercially sold by different global suppliers and Axxess XY. For these trials, all xylanase inhibitors from wheat were extracted. The inhibitors, together with the respective xylanase, were incubated at 40°C (to mimic bird body temperature) for 30 minutes. The loss of xylanase activity was then calculated by analysing remaining activity after incubation (Figure 2) There were varying levels of activity loss observed in the different commercially-sold xylanases. With some xylanases the losses were alarmingly high. However, Axxess XY was not inhibited at all.

Consistency

Xylanase inhibitors are present in all cereal grains and, unfortunately, heat tolerant (up to 90°C, with 75% of inhibition activity still retained). Regardless of the diets involved, it is possible that the xylanase used may encounter xylanase inhibitors, resulting in loss of activity. More importantly, this can lead to inconsistent performance. For effective, consistent and better performance of NSP enzyme application, it is vital to use a xylanase that is resistant to xylanase inhibitors.

References available on request.