Development of the fixed frame cutting machine

JF Equipment is in the process of developing a new auto cut-up machine, which will be available in the second quarter of 2009.

“We will be building a fixed frame ACM capable of producing a nine piece cut, as well as any variation of cuts which may be required by an abattoir,†says Pat Young, Sales Director for JF Equipment.

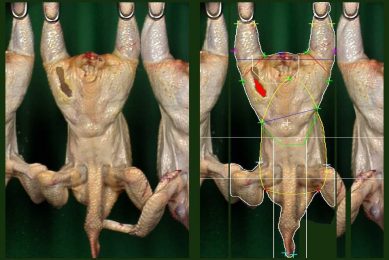

The company states that the job of cutting poultry automatically is a fairly complex one, and to accomplish this, a frame is made to carry a series of cutting devices, each designed to remove a specific section of the bird. There is a logical progression of parts removed in sequence as the bird is dis-assembled while moving through the machine starting with the wings, until finally the drumsticks are the last part to be lifted from the shackles. It will be optional to have a pocketed conveyor collecting the parts as they are cut, into a single pocket per bird, so that the original parts of any bird remain together as a unit.

JF Equipment’s fixed frame cutting machine will allow for the birds to be hung on special rotatable shackles. In the first unit a carcass diagonal cut is done to prepare the carcass for further cuts, which start at wing removal. The cuts made will be variable from anatomical to “Kentucky†style.

Since the frame system will allow for it, almost any conceivable cut could be carried out automatically, simply by fitting the right cutting unit into the correct position in the frame.

Related link: