Controlling conditions in the cooking zones for a better product

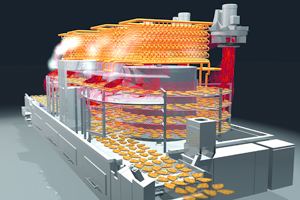

Cooking products to replicate a gourmet eating experience in an industrial oven involves considerable technical challenges. GEA Food Solutions have designed a multi-zone oven in which the cooking conditions can be controlled according to the demands of the final product.

By Technical Team, GEA Food Solutions

When confronted with choosing an industrial cooking solution, a straight comparison of technical specifications and features alone is not enough. It takes know-how and experience to support a customer in all aspects of the process. Dieter Gundt, senior food technologist at GEA Food Solutions, is one of the application experts that ensures cooking expertise is not only reflected in the design of the CFS CookStar, but also available to customers when they are developing and refining new products.

He says, “We didn’t start with a technology solution. We started by looking at how our customers wanted to cook their product. They need the taste, look and bite of home- or professionally cooked products on a much larger scale. But they also need to have the flexibility to switch quickly from product to product, so simplicity is a key consideration”. In addition to these culinary considerations and need for process flexibility, there are also business considerations like achieving higher yield and greater capacity without sacrificing cooking quality or consistency.“The solution was a multi-zone oven”, says Gundt. “It allows an accurate control of the temperature, humidity and dewpoint in each of the zones to be able to cover all the practical applications that we have ever come across. We found that it makes no sense to have complete zone separation, at least from a cooking point of view”.

Cooking to achieve consistent results

Without the need to apply two physically separated towers, the multi-zone oven can accurately control cooking environments to create consistent results – including browning and uniform core temperature across the belt width. For example, if called upon, it can achieve an 80 to 90°C (176 to 194°F) difference in temperature between the zones.

The multi-zone oven also offers accurate control of the cooking dewpoints of each zone and can maintain a difference of up to 21°C (38°F) between the two compartments. To make this tangible, reducing the cooking dewpoint from 80 to 60°C (176 to 140°F) at a cooking temperature of 150°C (302°F) reduces the humidity level by 40% from 300 g/m3 to 125. This is more than sufficient to satisfy all the customers’ application demands.

Roasted chicken parts

Roasted chicken parts like wings or drums (and whole birds) should combine an appetising brown surface colour with a juicy texture and a nice bite. To realise these qualities with a cooking process, the oven requires the possibility of browning the product with high heat, yet must also keep the moisture in the product. These demands are normally counterproductive.

The CFS CookStar overcomes this by cooking the product in the first zone with high air temperatures and lower humidity whereby the browning also takes place. In the second zone, the air temperatures are reduced and the humidity is raised to ensure that the product does not dry out and keeps it’s juiciness. If the roasting process also needs to deliver extra crispiness by reducing the fat layer underneath the skin, there is a version with an impingement zone.

The impingement technology adds a special dimension to cooking by providing a well-defined cooking area at elevated temperatures of up to 250°C (482°F). The impingement speed is fully adjustable to up to 25 m/s, enabling a dark brown product to be produced on demand. The airflow design also ensures an effective browning, even on the under-surface of the product – better than any other spiral oven can achieve.

Fighting skin slip

It’s a known problem that the skin from skin-on products like chicken drumsticks will contract and slip back during roasting processes. The only way to stop this degradation in quality and appearance is to fix the skin first by a low temperature treatment before a high temperature step roasts the product. The CFS multi-zone oven can perform such an extreme cooking process because of its ability to keep wide air temperature and humidity differences in its two cooking zones. In the first zone the skin will be ‘fixed’ by low air temperature and high humidity, followed by the roasting step in the second zone with high air temperature and low humidity. This offers a nice brown product with minimal skin slip.

Combined vertical/horizontal air flow

The latest generation CFS CookStar oven combines vertical and horizontal air flow, enabling it to confine the hot air and super-heated steam to the areas where they are needed. The additional vertical airflow in the middle of the cooking process enhances the efficiency and results when compared to spiral ovens with over 100% horizontal airflow or those with purely vertical airflow. Paul Verbruggen, product manager processing at GEA Food Solutions says, “The choice for the combined air flow was simple. During the development of the new oven, we tested and proved that the combined horizontal and vertical air flow ensures shorter cooking times which deliver so many advantages. Not only does it increase productivity and allow processors to swiftly change over to another product, but it also provides more consistent product quality, improved overall product colour, faster browning and a higher yield compared to pure horizontal ovens. By saving on cooking time, steam, belt cleaning and radiation losses, it also provides energy savings of up to 7%”.

Another benefit of this combined airflow configuration is related to controlling the air temperature across the full width of the belt as well as heat transfer to the products and their core temperature. These last two characteristics are influenced by a combination of steam condensation, convection and radiation. The airflow concept results in a great consistency of heat transfer to the products and a variation in core temperature of only 1 to 2°C (1.8°F to 3.6°F). This allows manufacturers to reduce their core temperature safety margins during cooking, which in turn, provides a financial benefit of a yield increase of up to 1%.

Lower cost of ownership

The design of the new generation multi-zone oven includes easy cleaning, more cost effective maintenance and a faster product change over. The CFS CookStar also features quick change belt washer brushes to enable quicker change over from vegetarian products to meat products (or vice versa) with minimum cross contamination. These and many other smaller enhancements result in a 15-30% shorter cleaning cycle using 10 to 20% less water and detergents, not only ensuring higher productivity but also enabling energy, water and cost savings. Up to 72 hours of continuous cooking between cleaning operations is possible.

“Reliability is critically important for maintaining productivity”, says Stefan Hanenberg, director of operations at Dalco Food, a processed meat company located in Oss, the Netherlands. “We have never had a machine from GEA Food Solutions that didn’t do exactly what we expected it to do. Our first CookStar oven has been running day and night for 10 years and we’ve never had an hour of unplanned downtime. It is still on its first conveyor belt. All these factors contribute to a low total cost of ownership”.

| Ready meals au gratin A challenge when cooking ready meals is the limited heat resistance of the meal trays which are usually made from thermoplastics. These can’t be heated above 160°C (320°F) during a cooking process, but for a high quality meal (especially with a brown au gratin surface), higher cooking temperatures are required. However while using CPET plastic trays with their normally limited temperature resistance of 150-160°C (302-320°F) elevated temperatures will deform the tray base and create sealing issues. This application problem is solved with impingement and a reduced humidity below the natural dewpoint. |