In ovo vaccination for everyone

In ovo vaccination has so far been limited for use in professional large size hatcheries. But Pfizer Animal Health Global Poultry has now introduced a smaller size version of their Embrex Inovoject device for small and medium size hatcheries: the “Inovoject m”. Pfizer doesn’t compromise on their technology, however. The “m” has just a few options less. And it’s a manually operated, yet flexible device.

By Ad Bal

In ovo vaccination was introduced in the USA over 20 years ago by pioneer Embrex (nowadays Pfizer Global Poultry). Over the years in ovo has proven to be a very effective technology in order to obtain early immunity in day-old, mainly broiler chicks. It is an effective way of mass vaccination, which is clearly different from other species like swine, ruminants and companion animals.

The overall advantages of individual injection are clear. In the hatchery, every bird can be vaccinated, which in a flock can never be guaranteed. In the latter case, when vaccinating through the drinking water or by spray, there’s no precise dosage and according to Pfizer, often about 10-15% of the flock is not vaccinated at all. Vaccinating chicks in the hatchery therefore is a very precise and effective technology.

But there are also disadvantages. First, every chick needs to be handled which is labour intensive and time consuming. Also it causes stress among the chicks. And thirdly, there’s a lack of constant disinfection, since one syringe is used for vaccinating a large number of chicks.

High capacity machine

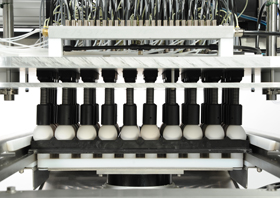

Pfizer found the solution to these disadvantages by introducing the Embrex Inovoject. This technology not only eases the vaccination process, it also enables the hatchery to vaccinate the chick already in the embryonic stage and thus obtain early immunity. With a capacity of up to 70,000 eggs per hour, the current Inovoject is a high-tech device, making it affordable for large scale hatcheries only. It is positioned in the transfer phase between setter and hatcher.

Pfizer found the solution to these disadvantages by introducing the Embrex Inovoject. This technology not only eases the vaccination process, it also enables the hatchery to vaccinate the chick already in the embryonic stage and thus obtain early immunity. With a capacity of up to 70,000 eggs per hour, the current Inovoject is a high-tech device, making it affordable for large scale hatcheries only. It is positioned in the transfer phase between setter and hatcher.

Depending on its configuration, also a nonviable egg detector and a vaccine saver are available, saving up to 10% of the vaccine. Currently, worldwide about 15 billion eggs are in ovo vaccinated on an annual basis, mainly in the broiler business. The USA is clearly taking the lead with, according to Pfizer, a 90% market share in the broiler industry for the Inovoject. In the USA and Brazil, the Inovoject is also used in turkeys.

Similar technology

In order to also make the in ovo technology available for smaller sized hatcheries worldwide, the “Inovoject m” is Pfizer’s solution. It is a mobile device with a capacity of up to 20,000 eggs per hour. The injection technology of this new device, is fully identical to the large size machine, but options like vaccine saver and nonviable egg detector are not available.

In order to also make the in ovo technology available for smaller sized hatcheries worldwide, the “Inovoject m” is Pfizer’s solution. It is a mobile device with a capacity of up to 20,000 eggs per hour. The injection technology of this new device, is fully identical to the large size machine, but options like vaccine saver and nonviable egg detector are not available.

Transfer from the setter to the Inovoject m is a manual task, simply by moving the egg flats underneath the vaccination head and push the buttons. Currently it complements the egg flats of Petersime, Chick Master and Jamesway. The Inovoject m is a small and versatile, mobile device. As a result it can be used everywhere in the hatchery, rather than in a fixed routing.

Technology and biology

Like with the large size Inovoject, the new Inovoject m remains property of Pfizer. Hatcheries use it on a lease basis. For this reason, Pfizer critically analyses new customers before they allow them to start using their in ovo technology. Once they meet Pfizer’s demands, the machine will be installed and the staff is trained adequately.

Like with the large size Inovoject, the new Inovoject m remains property of Pfizer. Hatcheries use it on a lease basis. For this reason, Pfizer critically analyses new customers before they allow them to start using their in ovo technology. Once they meet Pfizer’s demands, the machine will be installed and the staff is trained adequately.

From then on, Pfizer will also maintain the machine by checking and servicing it every nine weeks. After all, this system is truly high-tech. It is an integration of technology and biology which must be managed and monitored properly all the time. This is a specialism of Pfizer.

The new Inovoject m is likely to be a very promising new addition to the Embrex product range, opening up this technology for a wider audience around the world. Pfizer will officially launch the new Inovoject m during the upcoming IPE exposition in Atlanta, GA, USA.