Pulsed UV light to decontaminate eggs

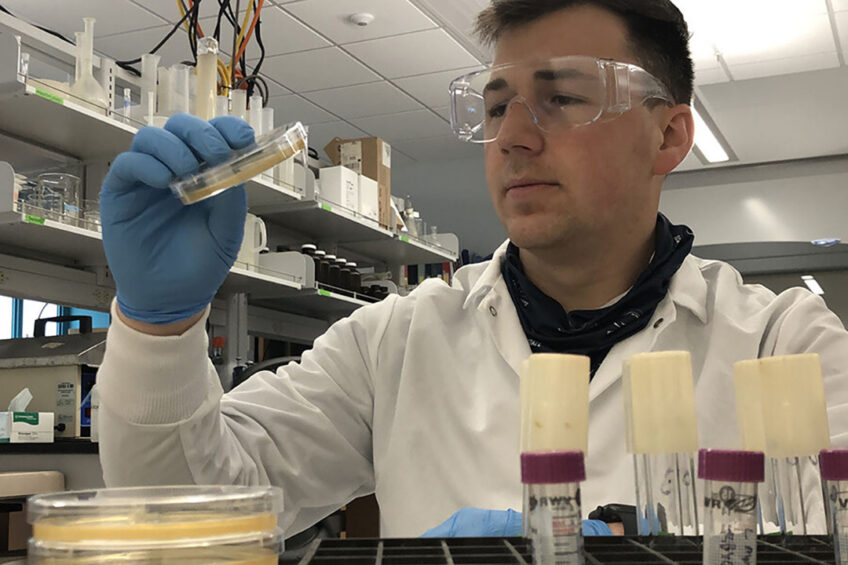

Researchers at Penn State College of Agricultural Sciences in the US have discovered that pulsed ultraviolet (UV) light can be an effective means of killing pathogens found on eggshells. This is a valuable finding for the poultry industry.

In the US, 9% of all foodborne illnesses are associated with eggs, according to lead researcher Josh Cassar, doctoral student in animal science. By reducing the microbial load on eggs, foodborne illness outbreaks associated with eggs and poultry meat can be reduced. Researcher Paul Patterson, professor of poultry science at Penn State, says this technology has the potential to achieve equal or greater microbial reductions in the absence of water or other chemical sanitizers, and the decontamination solutions currently available and widely used in the poultry industry. Not only is this an interesting solution for the poultry industry in developed nations but it also presents an interesting water-less egg sanitizing technology solution in developing countries where water may be scarce.

Washed and rinsed

Table eggs are currently washed with detergent and rinsed with sanitizers in the US egg industry. Hatching eggs, similarly, can be washed, or treated with chemical antimicrobial rinses or sanitizers. While UV light has been utilised with both table and hatching eggs as an additional antimicrobial step, pulsed UV light results in more acute delivery of UV light resulting in a greater microbial kill.

UV light versus pulsed UV light

Cassar explains that pulsed UV light delivers a much higher intensity of UV light to the surface of the eggshell and is therefore significantly more effective, resulting in a greater microbial reduction in a shorter period of time than conventional UV light treatment. “Pulsed UV light has a broad spectrum (100-1100 nm) emitted from a xenon flashlamp that is delivered in a series of pulses (100 ns to 2 ms) with over 50% of the energy originating from the UV region (100-400 nm),” notes Patterson. “The main germicidal mechanism of PUV light is the formation of DNA thymine dimers as a result of UV exposure. Secondary germicidal mechanisms result from longer wavelengths in combination with the short pulses that produce localised heating and micro-vibration, respectively, that contribute to microbial cell membrane collapse and death,” he says.

Cassar explains how the experiment worked using components of a commercial egg grader: “As the egg rotates on its long axis along the way, the entire surface of the eggshell is exposed to the pulsed ultraviolet light energy, and the 27 seconds of exposure in our experiment resulted in an acceptable germicidal response,” says Cassar. “At three pulses per second, each egg is exposed to nearly 90 pulses, and each pulse has a duration of 360 microseconds – an extremely short duration pulse.”

Hatchability unaffected

In addition to the food safety concerns of table eggs, the decontamination of hatching eggs is also important for maintaining good chick health. When hatching, chicks are exposed to micro-organisms present in the environment, including those on the surface of eggshells, some of which can be pathogenic. Therefore, the study also evaluated the effects of pulsed UV light treatment of hatching eggs on both embryo and chick growth. Using the same system, 4 batches of 125 fertile eggs were treated with the same and greater intensities of pulsed UV light. No significant negative effect was evident from the pulsed UV light treatment on the percentage of fertile eggs, hatchability or hatch, nor were there any significant effects on post-hatch observations, including chick livability and average bird weight.

“Our research supports the application of pulsed ultraviolet light as an effective antimicrobial intervention for both table and hatching eggs,” says Cassar. “If the egg industry embraces pulsed ultraviolet light technology and applies it in its processing operations, food safety would be improved because of the reduced pathogen presence on the surface of the eggs.” Patterson confirmed that previous research undertaken by the team showed between 1 to 7 log reductions in Salmonella and E. coli depending on the organism and the intensity and duration of pulsed UV light exposure.

Ease of delivery

The greatest advantage of this method of decontamination is its ease of delivery of the antimicrobial technology, says Patterson: “No chemicals to purchase, store, mix, deliver and dispose to the environment.” He further notes that the technology is especially promising because it appears to have no negative consequences for the vital hatching egg component of the business, even at 10 times the UV light intensity used in the table egg study. This, says Patterson, would improve chick health and would therefore, in turn, assist in easing the financial constraints caused by poor chick quality resulting from chicks getting sick from early exposure to microbial pathogens.

The study was published in Poultry Science.