The importance of insulation in poultry housing

Photo: Jan Willem Schouten.

There is no doubt that insulation is of utmost importance in maintaining a good climate in poultry houses. Regardless of whether it is summer or winter, insulation helps to reduce costs and improve bird performance. But what material, and how much of it, should be used?

Regardless of the type of poultry house, there must be some insulation. This is a requirement for open-sided houses as well as for those that are based on a controlled environment. Most of the insulation is attached to the roof as this is the area of greatest heat loss during cold weather and the area that is exposed to the sun’s rays during hot weather. But one should remember that insulation of a poultry house should minimise the transfer of heat from inside to outside and from outside to inside, regardless of whether it is through the roof or the walls. Insulation will help you to keep the warmth inside in winter, saving on heating costs, and in summer it will keep the heat outside, reducing heat stress and ventilations costs.

Controlling heat transfer in the poultry house

In general heat can be transported in 3 ways:

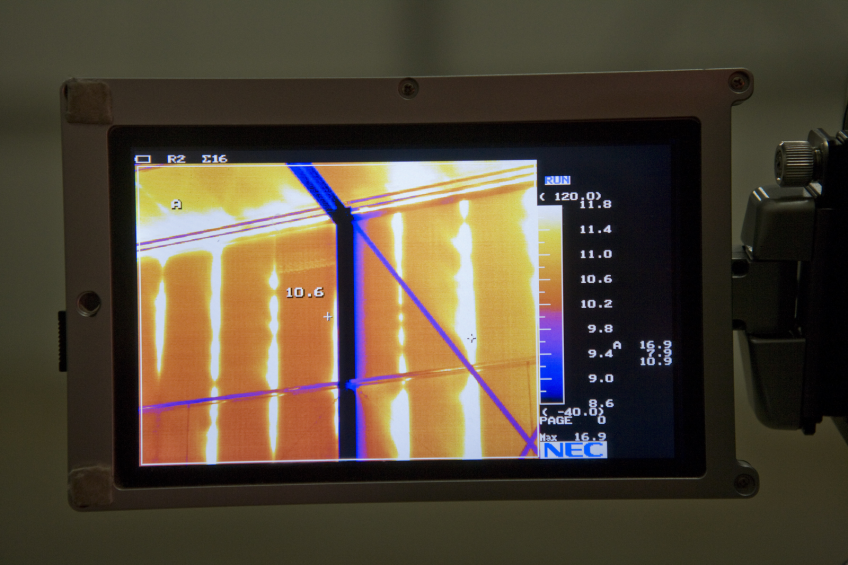

- Radiation: Heat transport by radiation is manly by means of infra red rays. Local heating systems like infra red lamps make use of this means of heat transport. All the energy on earth comes from the sun by way of radiation.

- Conduction: Conduction means that heat is transported trough a material. Some materials, such as metals, are very good conductors, other materials, like dry air, are very good insulators.

- Convection: Convection is heat transport by means of air. For example if you have a warm room and outside it is cold when you open the door the heat will be transported to outside by means of convection.

This means that optimum insulation should reduce all 3: radiation, conduction and convection. We can reduce radiation by making use of reflective materials. Conduction can be reduced by making use of materials with a lot of dry air (like foams, rockwool or glasswool). Convection can be reduced by closing any unnecessary openings.

The image below was provided by Roodbont Publishers and is part of the Think, Look, Act series that will be published weekly on World Poultry. Visit the website to learn more. Hover over the icons within the image for more information.

Insulation value

The efficiency of any insulation material is rated as its ability to resist the transfer of heat through it. In the building profession, the thermal conductivity of materials is expressed as the l (lambda) value of the material.

- The l (lambda) value of a material is defined as the amount of heat (Watts) which is conducted through one square metre of material which is also one metre thick (so, 1m3), given a temperature difference between the two sides of the material of one degree Centigrade.

- The K-value of a construction is defined as the amount of heat (Watts) which is conducted through 1 square metre of a construction, given a temperature difference between the two sides of the construction of one degree Centigrade.

- The l–value is the amount of resistance that heat experiences while passing a construction.

- The smaller the l -value, the less heat is conducted and the better the R-value (thermal resistance). Because each type of wall or roof has its own thermal resistance (R-value), the sum of the different l-values of the different materials used will give the R-value for the wall or roof. The higher the R-value of a construction (wall-floor-roof) the less heat is conducted.

- So the higher the K-value of insulation material the lower the R-value.

What affects insulation?

Factors which influence the insulation value of a construction include:

- The transfer resistance. The transfer resistance is due to the time which it takes for heat to pass from the indoor air to the inside wall and from the outside wall to the outdoor air. In our calculations we assume the R-value for the transfer resistance to be 0.17.

- The thermal conductivity (l -value) of each component part of the construction.

- The presence of cavities. Each cavity tends to increase the R-value of the construction by 0.17 (W/m2/K).

- Reflective finishes. Heat transmission due to radiation can be reduced by applying reflective finishes to surfaces. Aluminium reflects all heat rays, provided it stays shiny and the shiny side is in contact with the air. The R-value for aluminium foil is 0.20 (W/m2/K).

- The thickness of the material.

All these aspects play a role in creating a well-insulated environment. Since walls and roofs are made of different materials, a number of calculation examples indicate how to calculate the R-value of a poultry house, and what the minimum standards are for poultry houses in temperate climates.

Technical criteria

When choosing insulation material one has to look at the effectiveness of different options. The effectiveness depends on the theoretical and physical characteristics of the material, but also on how the material has been installed. In the real world, and especially in the rough environment of livestock production, one should also consider a number of technical issues. Insulation material should repel moisture and should be dry when being installed. Once installed, the material should not be allowed to take up moisture (vermin proof). In addition, insulation material should be fire proof, durable, easy to apply, present a high mechanical resistance and should require little maintenance. That is not all. Insulation material should also be wild bird, rodent and insect proof. If that is not the case, the material should be protected against the invasion of these destructors. This also counts for the material that is within reach of the birds inside the house. Once moisture, insects or rodents have access to the insulation material it quickly loses its insulation value.

Insulation in poultry houses can impact the birds’ health. Visit World Poultry’s health tool to learn everything you need to know about poultry health.