Vencomatic focuses on the egg for optimising profits

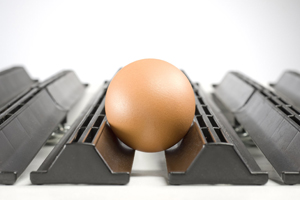

From the very first moment an egg is laid until it reaches its final destination, a commercially produced egg travels a long and tough journey. On this journey it faces numerous impacts and possible contamination sources. Vencomatic Group focuses on perfecting every detail of this journey, calling it the “Egg way”.

Their poultry and technical specialists evaluate and optimise every little step to protect the eggs from damage or contamination. Vencomatic Group strongly believes that optimising the Egg way is the only way to maximise profit for poultry producers with today’s tight margins.

Extensive research shows that carrying an egg from the nest to the hatchery or the retailer can be managed perfectly if you have the knowledge of every single move the egg experiences along its way. At VIV Europe Vencomatic Group demonstrates their proven solutions that contribute to the Egg way. Furthermore, the Dutch company presents several innovations to successfully ensure the Egg way in a perfect condition, such as:

- A perfect egg way starts with a healthy hen laying a maximum number of eggs. A global problem and risk for the hen’s health is red mite, which causes major economic losses resulting from suboptimal productivity. The revolutionary Q-perch (patent pending) is the only true environmental and bird friendly way to eliminate the problem of red mite. Resting on this innovative perch, birds are safe from red mite. As red mites do not get the chance to feed on the hens, the population never develops and the use of pesticides is history.

- At the heart of many Vencomatic systems is the laying nest. The Vencomatic nest is based on Vencomatic Group innovations, such as the Vencomat, the tipping floor and the egg belt. Innovations that make the difference along the Egg way ensuring outstanding egg quality. The well-known Vencomatic nest is integrated in the Bolegg Gallery, a new aviary system that combines user friendliness with a clever and economic design.

- For Vencomatic Group, the Egg way ends in the broiler house with on-farm hatching (patented). Previously on-farm hatching was only available with the Patio system, with the X-Treck this is now possible in traditional floor houses. The X-Treck enables direct post-hatch feed and water access and eliminates the stressful events of chick handling and transportation, providing an optimal start for chicks on the farm.

John Bierens, sales director europe, states: “Being successful in modern poultry production demands not only a high level of management but also perfect equipment. On its journey from nests, belts, egg packers, graders and transport to the hatchery or the retail, the egg encounters many different materials and machines. At Vencomatic Group we realise that each single system must be designed to maintain the perfect condition of the egg, but precise interconnection of systems is equally important”.

Vencomatic Group, combines three well-known brands; Vencomatic, Agro Supply and Prinzen to offers a full range of systems for all types’ of poultry farms.