Where do your eggs come from?

In most countries, it is required by law that each produced product has some form of traceability. For eggs, this means that the producing farm should be known so consumers can verify that the eggs they want are actually in the egg packs they buy.

Traditionally, the accuracy of tracking and tracing of eggs was very limited because the process of collecting this information is complex and challenging. Think about it; it is quite reasonable that a large egg packing station receives eggs from more than a hundred farms and produces over 50 different retail products from all these eggs.

The importance of traceability

Especially for the alternative egg producers, for example, the free-range and organic eggs. In many cases, these eggs are for smaller batches of eggs per farm. To keep up with the manual administration of every egg is almost undoable and costs a considerable amount of money. However, the information is paramount because if food safety issues happen, supermarkets need to quickly identify the source of these outbreaks so they can remove the contaminated eggs from the shelves. Therefore, we need a system that tracks all this data in the egg industry.

In case of an inline egg packing station, where the egg grading machine is on the same location as the farm, this is relatively simple to accomplish because all the eggs come from that particular farm. It is a lot more complicated at an offline packing station, where the egg grader receives eggs from multiple farms. These eggs are graded in different trays for various supermarkets. The only affinity between the origin and destination of these eggs is the computer from the egg grader itself.

Simple and quick reference point

For many years Moba’s Omnia egg grader line has traceability as a standard feature. With just a few clicks it is possible to find the origin of the eggs in a specific product (‘tracing’), and with a few more clicks a list is generated showing the eggs of this source’s destination (‘tracking’). Tracking and tracing all this information is not always enough. Sometimes linked information needs to be printed on eggs, other times on consumer packs or cartons or even on larger shipping units such as cases, displays and pallets. To print this information, we need to link to ERP systems or branch-specific software suites. The Omnia is also equipped with this.

Beside origin and destination, your egg grader collects a lot more data. To know every single detail of an egg can make a huge difference in your business. With the iMoba app, the ever-growing cloud solution for the Omnia line, all this information is fully automatically collected. iMoba is the next step in traceability and data collecting!

Traceability as a marketing instrument

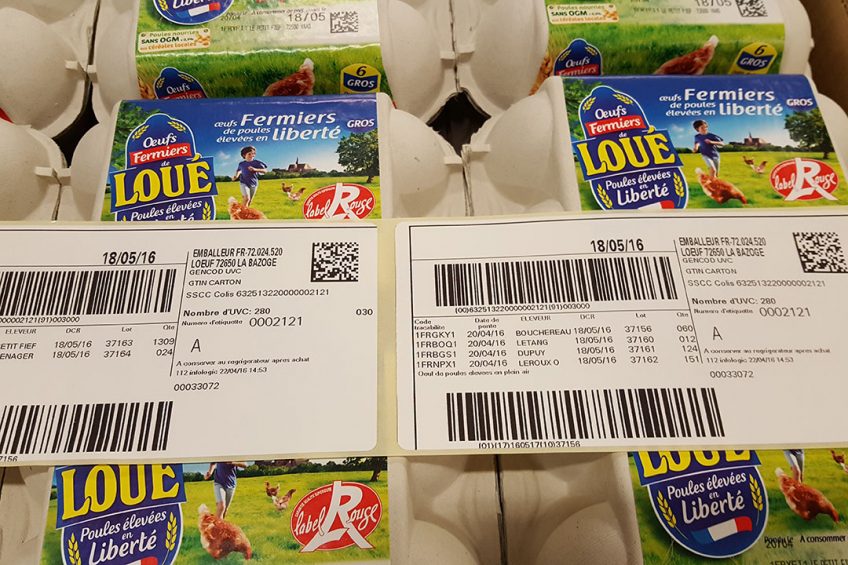

As a manufacturer of grading, packing, and processing equipment in the egg industry, Moba understands the importance of traceability. In many different projects Moba has proven to be able to answer many varying customer demands, sometimes driven by legislation or retail requirements, but in more situations to create a unique selling point for the produced products by going one step further and using traceability as a marketing instrument for premium egg products.

To read more about the possibilities, Moba offers for traceability