Spectroscopic in-ovo sex determination in practical and future use

Germany introduced a ban on culling day-old layer males on 1 January 2022 and more European countries will follow in the near future. Since the summer of 2020, Lohmann Deutschland, a subsidiary of EW Group, uses hyperspectral imaging for sex determination, specifically for brown layer breeds. The Cheggy machine, as it is known, from Agri Advanced Technologies (AAT), is non-invasive, fast and very accurate with low sexing errors.

The Dorum Hatchery in northern Germany was one of the first hatcheries in the world to implement the Cheggy machine. This enables accurate determination of the embryo’s sex in the second third of incubation.

It is no coincidence that this Cheggy machine is at the Dorum Hatchery. The hatchery is owned by Lohmann Deutschland, which, like the inventor of Cheggy, Agri Advanced Technologies GmbH (AAT), is also a fully-owned subsidiary of the EW Group.

In an interview, Jörg Hurlin, managing director of AAT, was asked a number of questions about this new technique. He explained that research on various in-ovo techniques to determine the sex of an embryo in the egg has been ongoing in the EW Group since 2008.

“AAT was founded in 2015 with the goal of developing market-ready automated sexing techniques. It is a long road to get from a research project to an accurate, reliable and practicable process in a commercial hatchery,” he said.

To achieve this, AAT works with various research teams and commercial companies in Germany and abroad. For its technical implementation, AAT relies on the know-how of partner companies, like Innovatec Hatchery Automation BV in the Netherlands.

Growing consumer concerns

In recent years, the culling of male layer chicks has increasingly become a thorn in the side of animal welfare organisations, retailers and consumers, says Hurlin. “That’s why legislators in Germany reacted by introducing a ban on culling day-old male chicks. We have also noticed that there is growing concern in several other EU markets, like France, the Benelux, Italy, Spain, and Austria. This trend has led us to rethink long-established hatchery processes, as we try to modernise and adapt the way we work to the animal welfare demands of the consumer.”

In France, for example, by 1 January 2023, all hatcheries were required to determine the sex by day 15 of incubation. And in Italy, no culling of day-old chicks will be permitted from 1 January 2026.

With the hyperspectral method it is possible to sort chicken embryos on day 13 of incubation, which is similar to other practical approaches in the second third of incubation. Briefly, the eggs placed in a closed chamber are illuminated from below with halogen light while the image is captured above by a special camera. Based on the spectra received, the sex of the embryo can be determined. The eggs with embryos classified as female are then incubated further, while unfertilised and ‘male’ eggs are sorted and removed.

High capacity

The hyperspectral measurement technology that Cheggy uses, has several advantages. The highly accurate procedure (currently greater than 96%) can be fully automated and more than 20,000 eggs can be tested per hour. “Of course, the speed of sorting is very important from a commercial point of view,” said Hurlin.

In total, one Cheggy machine can process 200,000 to 300,000 female chicks a week, which is about 10 million female chickens on an annual basis. But the most important aspect of the Cheggy technology is that it is a non-invasive method and the eggshell does not have to be opened or pierced. “Therefore, there is no risk of contamination or injury to the embryo. Thus, there is nearly no loss of hatchability which further contributes to animal welfare,” said Hurlin.

The fact that the eggs are taken out of the setter for in-ovo sexing for a short time is not critical because at this stage, the embryo is robust and egg handling does not disturb development. Finally, no consumables, like chemicals or test kits, are necessary in hyperspectral measurement technology, making the method very environmentally friendly, resource saving and cost efficient.

‘Avoid wasting money’

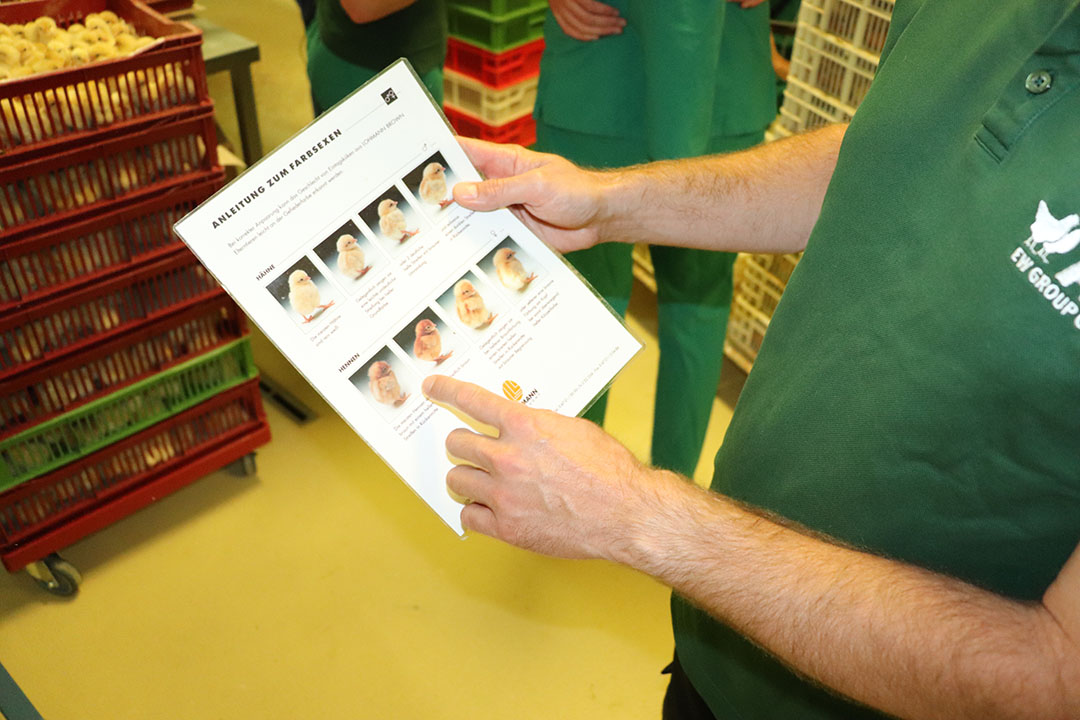

The Cheggy method achieves an accuracy of 96-98%, so an average of up to 4% male birds will hatch. As the breed used is feather sexable, the males can be selected directly after hatch. According to the AAT director, there are no legal rules on how accurately an in-ovo machine must work, but the German regulations require that the sexing errors (males) be grown for 10-14 weeks. The male chicks are grown on rearing farms in Germany and Poland.

“We have to bear in mind that the feed conversion of these males is in no way comparable to that of a modern broiler,” said Hurlin. “So, of course, a commercial company wants the accuracy to be as high as possible to avoid wasting money and resources. The growing of these male chicks costs money and is not sustainable, all the more so in a time of growing concern about climate change and resource consumption.”

With manual selection the hatchery has to fill in a lot of information on a special form to be able to justify everything to inspection authorities, like the German Association for Controlled Alternative Animal Husbandry (KAT). Hurlin: “AAT is very transparent when it comes to figures and production data. We are the only provider of technologies that has published data and scientific results.”

In mid-2022, Lohmann Deutschland had a world first with the in-ovo sex determination of an organic layer flock. And as the AAT director noted, this is a very favourable development for the organic layer sector, given that the growing of organic males is extremely costly due to the high feed prices. “Compared with all other methods, sex determination using the Cheggy machine offers by far the best price.”

Only brown layers

The Cheggy machine is already in use in several countries in Europe. “In Australia, the UK and many parts of Asia, for example, consumers prefer brown hens or brown eggs, so the Cheggy machine would be useful for hatcheries in those countries, too,” says Hurlin.

But there is also a growing demand for in-ovo sex determination in markets and countries that sell mainly white eggs, like the United States. Here the hyperspectral method is not suitable, however. Hurlin: “This year Lohmann Deutschland ran a test with the Ella machine of In Ovo from the Netherlands. This method detects the sex of an embryo by analysing specific biomarkers in the allantoic fluid using mass spectroscopy. “Unfortunately, the results of this test were not as expected, so the machine is currently not in use in Germany.”

The AAT director emphasised that a practicable method for in-ovo sex determination must be accurate and reliable, but also robust, cost-effective and fast enough to meet the requirements of modern hatcheries. “It is a rocky road from a good idea to an industrial application used on a daily basis – AAT knows that very well. Techniques may work at laboratory level but that does not always mean they will work in practice in a commercial setting.”

Spectroscopy before day 7

The German government’s plans are by 1 January 2024 only to allow in-ovo sexing techniques that can be applied within the first 7 days of incubation. Hurlin: “Today, however, worldwide, there is no existing technology to determine the sex of an embryo in the first third of incubation that is market-ready. Because the question of pain perception for the period between day 7 and day 15 of incubation has not yet been answered, we have a research project at the University of Dresden focused on the use of spectroscopy for early sexing.”

In this project they are currently working on a spectroscopic method that can be applied before day 7 and which is suitable for both white and brown layers. The process is as follows: first, the air cell within the egg must be detected. Then the shell is perforated with a CO2 laser and the lid of the shell is lifted. After the sex has been determined contactlessly using a spectroscopic method aimed at an exposed blood vessel of the young embryo, the shell is re-sealed. The eggs classified as female are incubated further and the sorted male eggs that are removed can be used as a high-quality protein source.

As previously noted, the implementation of a new automated method is often full of challenges. And until a rapid and reliable sorting method before day 7 is market-ready, the question arises of what to do with the rejected male embryos in a way that is animal welfare compliant and acceptable to consumers. Electrical stunning of the embryos in the egg – a method developed by AAT in 2020 – may be a way to interrupt the development of the sorted male embryos that is humane.

“The additional use of the stunning technology puts an end to the discussion about pain perception. The goal remains to enable sex determination at the earliest possible time. But the combination of non-invasive hyperspectral measurement technology and embryo stunning is clearly an improvement on the current situation,” said Hurlin.